Wednesday, 1 March 2023

Understand the Role of Six Sigma in the Energy Industry

Wednesday, 9 February 2022

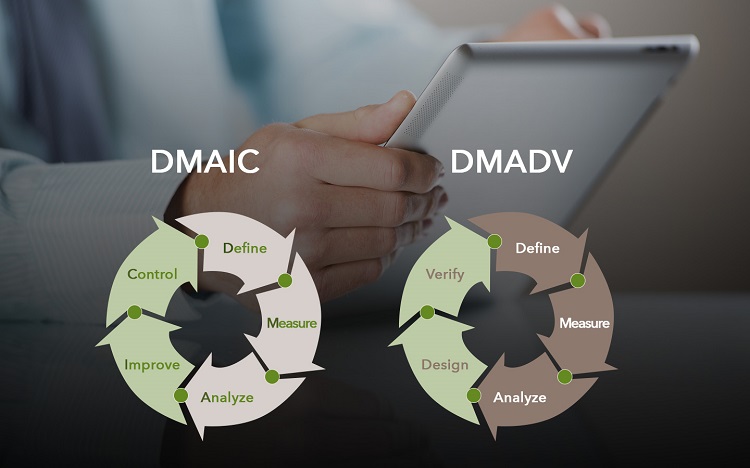

Difference between DMAIC and DMADV

1. DMAIC :

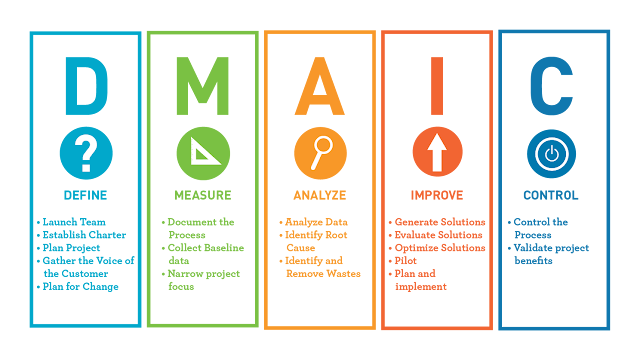

DMAIC is a part of the six sigma program which stands for Define, Measure, Analyze, Improve, and Control. DMAIC is a business strategy used to figure out how to improve processes while controlling costs. It’s an effective way for identifying the root cause of significant problems within your operations or the surrounding environment and then leveraging that knowledge to create a plan to solve it.

1. Define : First make sure that you have an objective in mind for what you want to improve and understand the problem as much as possible; this will help determine which process is being improved.

2. Measure : Next establish a baseline from which you can measure improvement by collecting data before any changes are made. This might involve making a control chart or collecting data from past projects/work because it contains groups of similar problems.

3. Analyze : After you have accumulated the data, analyze it to see what you can do to improve and get a baseline figure. This is a good time to use Control Charts and Pareto charts to see what improvements are occurring and which ones need more improvement.

4. Improve : At this stage you should begin making changes that will improve your process. One of the most important factors is changing system thinking in terms of getting rid of bad habits and creating new good habits. This part of the DMAIC cycle is for continuous improvement in your company and overall health of the system.

5. Control : After you have made all of the improvements, look at the data again to see how much it has changed and if there are any fluctuations or trends in your data. This will show you if you need to do more or less of something that you implemented.

2. DMADV :

DMADV is a part of the six sigma program which stands for Definition, Measurement Design Analysis Verification. These are general tools in the design process that we have found can be helpful to learn more about what is going on with your project.

The five phases are :

1. Definition : The definition stage is when you establish a common understanding of how the design will be performed.

2. Measurement : The measurement stage is when you collect data that helps you understand how your project is unfolding.

3. Design : The design stage is when you leverage all of the information collected in order to make wise decisions about the next steps you may take. The information that has been collected can be seen as an opportunity to drive the project to a better outcome rather than being viewed as a source of risk.

4. Analysis : The analysis stage is when you take all of the information collected in step 2 and step 3, and perform an analysis on it to help you understand what is really happening with your project.

5. Verification : The verification stage is when you compare expectations of how you want the project to unfold with how the project is actually unfolding. By doing this comparison, you are verifying that your original intentions are being met.

When to use ?

1. DMAIC : DMAIC methodology is used when the product has already been released out of the company, however there are issues or the product deviates from the customer’s demand.

2. DMADV : DMADV methodology is used when the product is not built and is currently in the designing & planning process. It is also used when the product could not be optimized and needs to be rebuilt.

Difference Between DMAIC and DMADV :

| DMAIC | DMADV |

| DMAIC is about the improvement and control process. It defines the business process. Find problem then solve it in a target of providing improved solution. | The design and verification process involves the redesigning of the whole process to come close to the requirement described by the customer. |

| It addresses the current processes of the project. | It addresses the design processes of the projects. |

| It works better with pre-existing projects. | It works better with new projects. |

| It is about minimizing the processes and correcting the errors. | While it is about preventing errors. |

| It uses quantitative tools. | It uses qualitative tools |

| DMAIC are usually considered for short term projects. | DMADV are usually considered for long term projects. |

| DMAIC gives specific solution. | DMADV is not the whole solution process, it is a part of the design solution. |

| It is about correction. | It is about prevention. |

| DMAIC controls future process performance. | DMADV verifies the design performance. |

| It is initiated from a problem. | While it is initiated from an innovation solution. |

Wednesday, 22 December 2021

Lean Six Sigma Explained

If you are looking to improve the way you carry out processes in your business and change the way things work, Lean Six Sigma may be an ideal option.

Nearly forty years old, this methodology has helped thousands of organizations around the world speed up production, improve efficiency and help save money.

You may be wondering if it is right for your business and if so, how to go about becoming a qualified practitioner. If the answer to both of these questions is yes, we’ve put together this short guide to help you find out more about Lean Six Sigma.

The history of Lean Six Sigma

Lean Six Sigma was initially devised by Motorola in 1985. The methodology came into being as a way for the company to reduce manufacturing issues and increase efficiency.

In fact, ‘sigma’ is a measurement of variation. With Lean Six Sigma, you want to reduce the number of variations (or defects) in your processes, as well as eliminate any unnecessary steps. Sigma strives to achieve near-perfect output, high-quality and consistent improvement.

This methodology was initially used by companies in the manufacturing industry. However, Lean Six Sigma has now been adopted by a wide range of different sectors including IT, healthcare, marketing and banking.

If your business has processes in place, then the Lean Six Sigma methodology can be applied.

What is Lean Six Sigma all about?

Lean Six Sigma is about data gathering, looking at issues analytically and measuring data to see if the processes put in place are working.

It’s also about continuous improvement. Once a problem has been resolved, it still needs to be monitored to see if there is a better, more efficient way of carrying it out.

Lean Six Sigma requires buy-in and commitment from everyone in the organisation, from the Managing Director to those on the shop floor. Everyone across the company needs to be aware of what is being done and how even the smallest changes can have a significant impact.

A good project manager skilled in the Lean Six Sigma Methodology will rally people behind any changes that need to be made.

What is DMAIC?

DMAIC is one of the critical methodologies that Lean Six Sigma uses. It is utilised to find and eliminate defects in a process.

DMAIC stands for:

◉ Define – define the problem, as well as what and who is needed to solve it

◉ Measure – quantify the problem and establish a baseline so you can see how things are improving

◉ Analyse – identify what is causing the problem and how you can change or remove these issues

◉ Improve – solve the problem, implement the changes and check that any amends made are working

◉ Control – ensure that the problem does not return, and that the process continues to improve over time

The belts of Lean Six Sigma

Six Sigma has a lot in common with karate. Both require precision, dedication and knowledge.

With karate, you receive a new colour belt when you pass your exams. With Lean Six Sigma, although you do not receive a physical belt, the different grades are called ‘belts’!

People with no formal Lean Six Sigma qualifications are known as ‘white belts’. After this, there are three different levels of accreditation.

Lean Six Sigma Yellow Belt

This is a short introduction to the world of Lean Six Sigma – ideal for those who may not be managing change but are involved in supporting the people that are.

Learn more about our Lean Six Sigma Yellow Belt

Lean Six Sigma Green Belt

The next step on the Lean Six Sigma ladder, a Green Belt, is a good starting point for project managers. This course introduces them to the problem-solving frameworks that Lean Six Sigma utilises.

This is a lifetime certification and does not need to be recertified.

Learn more about our Lean Six Sigma Green Belt

Lean Six Sigma Black Belt

In karate, a black belt means that you have mastered all there is to know and are ready to lead others. The same applies to a Black Belt in Lean Six Sigma.

This advanced course teaches delegates how to drive change across the business as well as how to measure performance.

This certification needs to be renewed every three years.

You don’t have to complete Lean Six Sigma Green belt before you take on this accreditation, but it is recommended.

If you want to take things even further, you can study for a Lean Six Sigma Master Black Belt. This shows that you can not only lead others but are qualified to teach them in Lean Six Sigma methodology too.

Learn more about our Lean Six Sigma Black Belt

Why is Lean Six Sigma so beneficial?

Lean Six Sigma has the following benefits for organisations.

◉ It improves productivity

◉ It improves quality

◉ It increases customer and stakeholder satisfaction

◉ It ensures compliance with government regulations

◉ It reduces waste

◉ It reduces operating costs

◉ It reduces risk

◉ It reduces employee turnover

It also has benefits for you too! Holding a Lean Six Sigma Qualification can increase your salary and help you get promoted to managerial roles.

Source: itonlinelearning.com

Thursday, 25 February 2021

What Is DMAIC?

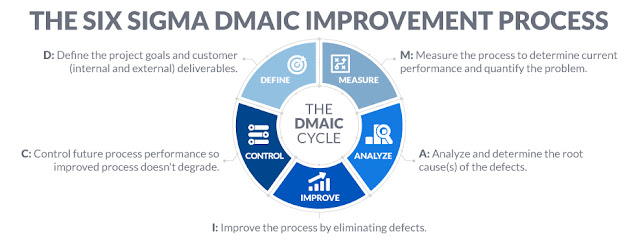

DMAIC is an acronym for Define, Measure, Analyze, Improve, Control. DMAIC is the process improvement methodology of Six Sigma that’s used for improving existing processes.

What Is DMAIC?

DMAIC Process Steps

Monday, 25 January 2021

Using DMAIC to Improve Another Improvement Process – CAPA

Six Sigma and its DMAIC (Define, Measure, Analyze, Improve, Control) methodology provide a structured process for solving problems and improving processes. For this project, our team used DMAIC to improve a problem-solving process used in the medical industry – the CAPA process.

Medical device companies are required to demonstrate compliance to the Federal Drug Administration (FDA) 21 Part 820.100 Corrective Action and Preventive Action (CAPA) to be able to sell medical devices in the United States.

The CAPA process at Medtronic complies with the regulations of the FDA and applicable international standards to address quality issues – device complaints, non-conformances and audit findings. The CAPA process is divided into three key phases and align with the DMAIC phases as shown in the table below.

| CAPA Phase | What Happens in Phase | DMAIC Phase Correlation |

| Investigation | Determine root cause | Define, Measure, Analyze |

| Action | Take corrective action | Improve |

| Effectiveness | Verify the success of the corrective action | Control |

Overview

Define

Measure

Analyze

Improve

Control

Monday, 5 October 2020

Case Study: Reducing Delays in the Cardiac Cath Lab

The Define Phase

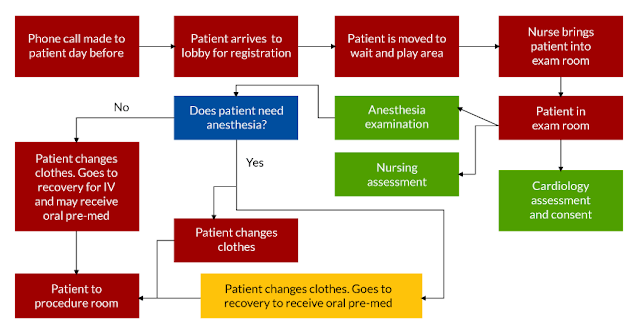

- Project Scope – This established the parameters for the project. The start point of the cycle was patient’s arrival at the hospital and the end point of the patient’s entrance into the cath lab. The charter also described areas outside of the team’s scope, such as room turnaround time, which was the focus of another team.

- Business Case and Problem Statement – Baseline data indicated that 62 percent of the first cases were not starting on time representing 267 hours of lost staff productivity and unused procedure capacity annually.

- Goal Statement – A goal of 80 percent on-time starts was established.

- Team Members – The team for the project included the cath lab director, staff, cardiologists and anesthesiologists. The vice president of operations served as project sponsor and oversaw the work of the team.

- Timeline – A timeline including frequency of meetings, dates and times was agreed upon at the team’s first meeting and proved essential to keeping the project on track.

The Measure Phase

The Analyze Phase

| X | Test | Results | Statistically Significant? |

| Nurse | Test for Equal Variances | p=.725 | No |

| Nurse | Moods Median | p=.583 | No |

| Nurse | Regression | p=.762 | No |

| Latest Assessment Time | Moods Median | p=.432 | No |

| Latest Assessment Time | Test for Equal Variances | p=.132 | No |

| Latest Assessment Time | Regression | p=.177 | No |

| Anesthesia Yes/No | Moods Median | p=.710 | No |

| Anesthesia Yes/No | Test for Equal Variances | p=.318 | No |

| Oral Pre-Med Yes/No | Test for Equal Variances | p=.981 | No |

| Oral Pre-Med Yes/No | Moods Median | p=.288 | No |

| Anesthesiologist | Moods Median | p=.389 | No |

| Anesthesiologist | Test for Equal Variances | p=.013 | Yes |

| Anesthesiologist | Regression | p=.625 | No |

| Patient Arrival | Test for Equal Variances | p=.909 | No |

| Patient Arrival | Moods Median | p=.615 | No |

| Difference vs. Card Assessment | Regression | p=.042 | Yes |

| Time Patient on Table vs. Card Assessment | Regression | p=0.00 | Yes |

| Difference vs. Anesthesia Yes/No | Regression | p=.532 | No |

| Difference vs. Nursing Assessment | Regression | p=.658 | No |

The Improve Phase

| Data Categories | Baseline Data | Improve/Control Data |

| On-Time First Case Start | 38 Percent | 83 Percent |

| Baseline Z | 1.44 | 2.47 |

| Median | 13 Minutes | 0 Minutes |

| Mean | 38.24 Minutes | 6.33 Minutes |

| Standard Deviation | 55.62 Minutes | 22.4 Minutes |

The Control Phase

Wednesday, 4 March 2020

Case Study: Surmounting Staff Scheduling at Valley Baptist Health System

In 2002, Valley Baptist Health System began to implement GE’s Six Sigma approach as a rigorous methodology for process improvement and a philosophy for organizational transformation. The adoption of Six Sigma at Valley Baptist fostered a revitalized culture that embraces the voice of the customer, breaks down barriers to change and raises the bar on performance expectations. Through this initiative, the team at Valley Baptist began to examine the most critical opportunities for improvement and select projects that would align with strategic objectives and produce measurable results.

As with most healthcare providers today, maintaining appropriate staffing levels and improving productivity are among the top concerns at Valley Baptist. During the initial wave of Six Sigma training projects, the team at Valley Baptist launched an effort to review and improve the staff scheduling process for one nursing unit in orthopedics. Within this particular unit, there had been a history of overtime and use of agency hours that did not seem to correlate with changes in patient volume. Patient census would fluctuate while staffing levels remained the same, and the higher hourly wage for overtime and agencies had begun to strain the overall labor budget.

The primary focus for this project was to improve the unit’s ability to responsibly meet staffing targets while protecting the quality of patient care. It is a challenge to reach that optimal level – avoiding overstaffing yet appropriately meeting daily needs. Paramount in this effort was the notion that targets would be met without adversely impacting customers. Patient satisfaction scores had to remain constant or increase, and this mandate was built into the project and measured through the use of upper and lower specification limits.

A cross functional project team was assembled including the chief nursing officer as sponsor, the assistant vice president from human resources, the nursing house supervisor, the nurse manager from the cardiac care unit, a representative from IT and a charge nurse. The introduction of any new change initiative can elicit skepticism, but since Six Sigma concentrates on fixing the process rather than assigning blame, once the approach was understood much of the skepticism subsided. Stakeholder analysis and other CAP (change acceleration process) tools helped to surface concerns and improve communication.

Also supporting this project were metrics to measure productivity for nurses and managers that had been introduced through the adoption of Six Sigma. The dual emphasis on productivity and quality provides a framework for offering cost effective care and aligns with the customer-centered mission at Valley Baptist.

Defining the Goal

During the Define phase of the project, the team concentrated on clearly identifying the problem and establishing goals. The nursing units in general had struggled to meet their staffing targets and were over budget on labor costs. For this project, the team decided to focus on one orthopedics nursing unit based on three criteria: the unit was not extremely specialized or unique so it offered the best representation of nursing as a whole; the manager was very supportive of the initiative; and this unit offered clear opportunity for improvement and results.

To understand the current scheduling process, the project team used the SIPOC tool to develop a high-level process map. SIPOC stands for suppliers, inputs, process, output and customers. Inputs are obtained from suppliers, value is added through your process, and an output is provided that meets or exceeds your customer’s requirements. SIPOC is extremely useful during process mapping.

Measuring and Analyzing the Issues

As they moved through the Measure and Analyze phases, the project team focused on data collection and the identification of the critical “Xs” that were impacting staff scheduling. Historical data was gathered from the payroll system to analyze regular time, overtime, agency use, sick time, vacation, jury, funeral leave and FMLA. They examined 24 pay periods for each data point. Fortunately, the team was able to extract the data they needed from existing systems and avoid manual data collection, which is more labor intensive and can increase the project timeline.

Given the availability of continuous data for the “Y” or effect and the potential Xs or causes, regression analysis was the tool chosen to help the team understand the relationship between variation from the staffing goals and vacation, FMLA, sick leave, overtime, agency nurse usage, and so on. Through regression analysis, they were able to determine that three critical Xs could explain 95 percent of the variation: agency use, overtime and census. The next step would be to understand underlying factors – data would point the team to interesting findings that disputed their original theories.

The Improve Phase

During the Improve phase, the team used many of the CAP and Work-out tools. Such acceptance-building techniques are key to success, since improvements introduce changes in process and human behavior. The team conducted a Work-out session to develop new standard operating procedures for better management of overtime and agency usage – critical drivers in staffing.

The chief nursing officer attended the sessions to underscore the importance of this initiative from a leadership perspective. The project team used the process map to indicate where they might have opportunities for improvement, and then conducted separate Work-outs on each area. They brought in nursing staff, house supervisors and other stakeholders to participate in the search for solutions.

Never Assume

This project furnished a classic example as to how Six Sigma can be used to either corroborate or dispel original theories. Management at Valley Baptist had initially assumed they were over budget on labor costs due to sick leave, FMLA, vacation and people not showing up, which would have naturally necessitated the additional overtime and agency hours. The data and analysis proved those assumptions to be incorrect.

This project translates to $460,000 in potential savings for one unit. Conservatively, if it were spread across the health system the savings could exceed $5 million.

It turns out there were several factors contributing to the staff scheduling challenges. One illuminating aspect to come from the Work-outs was the realization that nurses didn’t like floating in and out of units – this came up in every session. There were also issues with the staffing matrix which attempted to set parameters based on volume. Compliance was not ideal, and the matrix itself was based on data that was not completely current. Another complication was that maintaining information in the matrix involved labor intensive, manual processes that were difficult to control.

The central metric of this Six Sigma initiative was worked hours divided by equivalent patient days. Valley Baptist Health System defines worked hours as those hours during which an employee was actually working – including regular time and overtime, and excluding non-productive hours such as sick and vacation time. Equivalent patient days is the volume statistic utilized within the Orthopedics Unit. It is the typical patient days number adjusted to reflect short-term observation (STO) patient volume.

The team discovered the use of overtime was not always need-based. Units would regularly schedule 48 hours for each nurse, with the extra eight hours of overtime built-in as “traditional” usage. This became an accepted practice and although in theory, adjustments are supposed to be made when the patient flow is lighter, this was not happening. On the form used to submit data the nurses would have to guess what hours they might actually work. The matrix might indicate compliance, but the payroll data actually showed them clocked in for 14-15 hours instead of 12.

Another critical issue is that the nursing unit lacked appropriate mechanisms for shift coordination and handoff. There were two fully independent teams between the day and night shifts, and there was not a smooth transition between them. Part of the problem stemmed from a lack of written guidelines governing the overtime between shifts. Nurses would finish their regular 12-hour shift and stay on overtime to complete tasks rather than pass them on to the next shift.

Results and the Control Phase

The development of new standard operating procedures has clearly had a positive impact on the organization. This gave staff a plan they can follow and established accountability. The unit began a process for transition meetings between shifts. The outgoing nurse now takes the incoming nurse to the patient’s room, introduces them and provides a report on the current status and whether there are outstanding orders. In addition to improving operations for the hospital, this change has also been well received by patients, as reflected in rising satisfaction scores during the pilot.

The project on staff scheduling has led to an overall reduction in the higher hourly cost of overtime and agency use, and has translated to $460 thousand in potential savings for this one unit. Conservatively, if this project were spread across the health system the savings could exceed $5 million. It is also important to note that this project started at the 0 sigma level and increased to Six Sigma for nine consecutive pay periods.

“At Valley Baptist, we continually seek opportunities to improve productivity,” said Jim Springfield, President and CEO. “This focus is critical for our future success and ability to meet patient needs.”

To ensure results are maintained, managers use control charts and trend reports with data from HR, time and attendance and payroll systems. This provides real time information on productivity, tracking worked hours versus patient days to show alignment with targets on an ongoing basis.

Organizational and Customer Impact

The bottom line is that nurses, management and patients are all happier as a result of this project. With the pilot in the Control phase, Valley Baptist has held Work-outs to determine how they might broaden the SOPs and implement this approach across the system in all nursing units.

“Staff has become much more flexible. We initially encountered some resistance, but using the CAP tools and working through the process helped to create a shared need and vision.”

Leadership involvement and support turned out to be a significant factor in the overall success of the project. This initiative represented a major culture change from previous CQI and TQM approaches to quality improvement. All previous efforts had involved hard work and good intentions, but prior to Six Sigma, they lacked the framework and rigor to institute statistically valid long-term results.

The health system is moving toward autonomy through additional Green Belt and Black Belt training with projects, and through participation in a Master Black Belt course at GE’s Healthcare Institute in Waukesha, Wisconsin. This experience provides instruction and interaction that prepares the MBB to come back and teach within the organization.

“Coming from the HR side, it’s important for organizations to know it’s possible to change the way you’ve always done things, and that employees will adapt to a new approach. If you can overcome the stress surrounding change you can realize increased efficiency. This is a positive way to control staffing without employing slash and burn techniques.”

Irma Pye, senior vice president at Valley Baptist, attended a conference in Utah with other healthcare executives. When the issue of performance improvement and staffing came up, someone mentioned they’d attempted to do a project on this and it had failed because they couldn’t afford to alienate and potentially lose good employees. Irma spoke up and let them know that based on her own recent experience, you can indeed address this issue and it can work if it is approached in the right way using the right techniques.

“Usually, when you ask the department manager to trim labor costs they think it can’t be done because it will antagonize employees . . . they’ll either take a job somewhere else, or stay there with negative feelings which impacts morale. This approach was able to affect change, while avoiding issues of layoffs or pay cuts.”

Monday, 2 March 2020

Six Sigma Software Development Case Study

Project Selection

While the selection process precedes a project’s Define phase, identifying an initial general goal, there is a chicken and egg relationship with Define as that goal is better understood and refined. We have an initial idea of our goal, but we may need to do some of the Define work before we know if the scope is reasonable. Project selection brings out another important consideration not directly addressed by Define – it establishes the link between candidate projects and corporate strategy (in one sense, these are the top level Ys).