Monday, 19 February 2024

Maximizing Your Career Potential with Six Sigma Certification

Monday, 17 April 2023

Benefits of Six Sigma

Introduction

History of Six Sigma

Understanding Six Sigma

Benefits of Six Sigma

Increased efficiency

Cost savings

Improved customer satisfaction

Better decision-making

Employee engagement

Competitive advantage

Conclusion

Wednesday, 5 April 2023

Six Sigma: The Key to Unlocking a Highly Engaged Workplace

What is Six Sigma?

How does Six Sigma work?

How can Six Sigma create a highly engaged workplace?

Conclusion

Wednesday, 22 December 2021

Lean Six Sigma Explained

If you are looking to improve the way you carry out processes in your business and change the way things work, Lean Six Sigma may be an ideal option.

Nearly forty years old, this methodology has helped thousands of organizations around the world speed up production, improve efficiency and help save money.

You may be wondering if it is right for your business and if so, how to go about becoming a qualified practitioner. If the answer to both of these questions is yes, we’ve put together this short guide to help you find out more about Lean Six Sigma.

The history of Lean Six Sigma

Lean Six Sigma was initially devised by Motorola in 1985. The methodology came into being as a way for the company to reduce manufacturing issues and increase efficiency.

In fact, ‘sigma’ is a measurement of variation. With Lean Six Sigma, you want to reduce the number of variations (or defects) in your processes, as well as eliminate any unnecessary steps. Sigma strives to achieve near-perfect output, high-quality and consistent improvement.

This methodology was initially used by companies in the manufacturing industry. However, Lean Six Sigma has now been adopted by a wide range of different sectors including IT, healthcare, marketing and banking.

If your business has processes in place, then the Lean Six Sigma methodology can be applied.

What is Lean Six Sigma all about?

Lean Six Sigma is about data gathering, looking at issues analytically and measuring data to see if the processes put in place are working.

It’s also about continuous improvement. Once a problem has been resolved, it still needs to be monitored to see if there is a better, more efficient way of carrying it out.

Lean Six Sigma requires buy-in and commitment from everyone in the organisation, from the Managing Director to those on the shop floor. Everyone across the company needs to be aware of what is being done and how even the smallest changes can have a significant impact.

A good project manager skilled in the Lean Six Sigma Methodology will rally people behind any changes that need to be made.

What is DMAIC?

DMAIC is one of the critical methodologies that Lean Six Sigma uses. It is utilised to find and eliminate defects in a process.

DMAIC stands for:

◉ Define – define the problem, as well as what and who is needed to solve it

◉ Measure – quantify the problem and establish a baseline so you can see how things are improving

◉ Analyse – identify what is causing the problem and how you can change or remove these issues

◉ Improve – solve the problem, implement the changes and check that any amends made are working

◉ Control – ensure that the problem does not return, and that the process continues to improve over time

The belts of Lean Six Sigma

Six Sigma has a lot in common with karate. Both require precision, dedication and knowledge.

With karate, you receive a new colour belt when you pass your exams. With Lean Six Sigma, although you do not receive a physical belt, the different grades are called ‘belts’!

People with no formal Lean Six Sigma qualifications are known as ‘white belts’. After this, there are three different levels of accreditation.

Lean Six Sigma Yellow Belt

This is a short introduction to the world of Lean Six Sigma – ideal for those who may not be managing change but are involved in supporting the people that are.

Learn more about our Lean Six Sigma Yellow Belt

Lean Six Sigma Green Belt

The next step on the Lean Six Sigma ladder, a Green Belt, is a good starting point for project managers. This course introduces them to the problem-solving frameworks that Lean Six Sigma utilises.

This is a lifetime certification and does not need to be recertified.

Learn more about our Lean Six Sigma Green Belt

Lean Six Sigma Black Belt

In karate, a black belt means that you have mastered all there is to know and are ready to lead others. The same applies to a Black Belt in Lean Six Sigma.

This advanced course teaches delegates how to drive change across the business as well as how to measure performance.

This certification needs to be renewed every three years.

You don’t have to complete Lean Six Sigma Green belt before you take on this accreditation, but it is recommended.

If you want to take things even further, you can study for a Lean Six Sigma Master Black Belt. This shows that you can not only lead others but are qualified to teach them in Lean Six Sigma methodology too.

Learn more about our Lean Six Sigma Black Belt

Why is Lean Six Sigma so beneficial?

Lean Six Sigma has the following benefits for organisations.

◉ It improves productivity

◉ It improves quality

◉ It increases customer and stakeholder satisfaction

◉ It ensures compliance with government regulations

◉ It reduces waste

◉ It reduces operating costs

◉ It reduces risk

◉ It reduces employee turnover

It also has benefits for you too! Holding a Lean Six Sigma Qualification can increase your salary and help you get promoted to managerial roles.

Source: itonlinelearning.com

Wednesday, 8 December 2021

Difference between Scrum and Six Sigma

1. Scrum:

Scrum is a lightweight framework for agile development. It is subset of Agile Software development process which is nothing but an iterative and incremental software development technology.

Scrum can be defined as an assembling of peoples and that represents a teamwork. A group of ten or less than ten peoples in which they have specific skills to perform their own task in a particular era. Scrum was introduced to develop, deliver and for satisfying the products in a multiplex habitat.

The team of scrum consists of a product owner, a scrum Master and the developers. It mainly focuses on the product and other roles as well.

1. Product Owner : Product owner represents the product’s stakeholder and it manages the requirement of the customer, also focuses on the productivity and betterment of business. This is the most important role which handles both the business sides as well as the developer’s side in the scrum team.

2. Developers : Developers plays a vital role here; they manage all the technical part for growth of the business. They also convey to the researchers, architects, designers, data specialist, analysts, engineers, programmer, for developing for developing or improvement of the product.

3. Scrum Master : Scrum master is responsible for removing the obstacles during the production or delivering. It also ensures that the scrum framework is obeying the methodologies of business or not and also in the growth of production. Scrum mainly helps the product owner to keep the backlog of the product, well-being of the business.

Workflow of Scrum :

In scrum workflow, it requires several steps those are:

1. Sprint Planning : In this method the product owner and the developers discussed together that which product backlog items should be given to the sprint. This sprint planning focuses on the correct executing and removing error to get a sprint goal and backlog.

2. Daily Scrum : Daily scrum given the overview of sprint goal. The developers with lack of their time they can check quickly and easily, assess the program, activity plans for the next 24 hour. The daily Scrum is limited for only 15 minutes.

3. Sprint Review : This process initiated at the end of the sprint. It authorizes the scrum team, the occasion to present the recent increment done to the stakeholders. It checks the improvement and the work process of the sprint.

4. Sprint Retrospective : This is the final step in sprint. This method ensures that what change could occur in sprint for the Improvement. This process resolves by collaborating all the members such as the product owner, scrum master, the developers, and the entire scrum teams for the betterment and progress of the business.

2. Six Sigma :

Six sigma it is a set of approach and which provide tools for processing and improvement. Six sigma was introduced by an American Engineer named as “Bill Smith” in the year 1986, when Bill Smith was working at Motorola company.

The term six sigma has been derived from statistical method. This mainly focuses on achieving profit and financial status. Six sigma is highly recommended for business growth and increment of profits as well. Based on statistical method we can easily detect the error in the system and also the cause of decrement in the business.

Six sigma always tries to succeed with its dedications and great efforts. It requires whole commitment with the entire organization and keeps everything in a detailed way so that it helps to understand quickly all the strategies. Abolishing dissimilarities, it saves our money and also reduces the faults.

Some of the most used tools for measuring and analyzing the process such as; Control Charts, 5 Whys, Root Cause Analysis, CTQ tree, Statistical Process Control, Process Mapping etc.

Workflow of Six Sigma :

The methodology of six sigma is based on two principles DMAIC and DMADV.

1. DMAIC :

DMAIC is derived from various words and having their specific meanings.

1. D: D stands for defining the customers requirement and project goals.

2. M: Measures the key point on the recent process going on.

3. A: Analyze the data. It analyzes data from the existing one for their benefits.

4. I: Improve processes. Examine and analyze for the progress.

5. C: Control future executions for the accurate outputs so that errors doesn’t comes again.

2. DMADV :

DMADV is also derived from various words.

1. D: Defines company and customer needs.

2. M: Measures CTQs (Characteristics that are critical to quality). It measures the product ability for growth and production and damages.

3. A: Analyze data from our computation.

4. D: Design the new method based on the preceding move.

5. V: Verify the pattern by a pilot run, applicating the new method and provide it to the owner.

Difference between Six sigma and Scrum :

| Six Sigma | Scrum |

| Six sigma focuses on the method of controlling and similarities through reducing of errors and disparity. | Scrum is based on Agile program management process which focuses to control the software and product development by repetitive progress methods. |

| It is based on DMAIC and DMADV principle. | It is based on DMAIC and DMADV principle. It is based on Agile principle. |

| It requires highly changes on the documentation and good strategy. | It only requires changes on the teammate’s interaction and customer partnership. |

| There is no need of teammates | There is need of good teammates for guidance. |

| In six sigma there is no need to verify their works to such other departments. | In scrum the process is considered and verified by various departments. |

| It is ideal for companies working on large scale projects where the requirements and functions/processes are clearly declared. | It is ideal for agile companies which work on projects with changing requirements. |

| Six sigma improves processes by eliminating waste and variations. | Scrum breaks down the project into short sprints. |

Friday, 20 August 2021

Best Tools and Techniques for Six Sigma

Six Sigma is a business theory focused on improving the quality of goods or services an organization produces by reducing differences in the production cycle. Six Sigma managers realize that when a production process comes up short on the strength to make high quality reliably, it will keep delivering damaged products until somebody intercedes and improves the process. Decreasing variation requires steady measurement and estimation as frameworks will in general disintegrate if not held under tight restraints. Throughout the long term, Six Sigma professionals have built up a lot of tools and techniques that address control, and critical thinking and improvement to dispense with imperfections and waste. Here is a couple of the most fundamental.

Best Tools and Techniques for Six Sigma

1. Standard Work

Standard work is the documentation of the accepted procedures for any process or undertaking at that given second. It is made and refreshed by the people who accomplish the work. It shapes the benchmark for development and assures measure consistency.

2. 5S Workplace Organization

An organized and well-stocked working environment fundamental in the mission to eliminate variety. The procedure includes completing 5 things that all beginning with S in both English and Japanese. They comprise of seiri (sort), seiton (set), seiso (Shine), seiketsu (standardize), and shitsuke (Sustain).

3. Control Charts

A process control outline is a chart used to chase how a process carries on overtime. Data points are plotted in a chart with an upper line for the normal (once in a while a middle), an upper line for the upper control limit, and a lower line for the lower control limit. Process control diagrams assist leaders with abstaining from freezing over each up and downswing. They avoid issues made about by just seeing normal outcomes, rather than the varieties of results.

4. Gemba Walks

The Japanese word "Gemba" signifies the real place. During a Gemba walk, the manager goes to where work is done regarded for the employees, asks inquiries, and conceivably identify open doors for development.

5. Hoshin Kanri

Hoshin Kanri (in any case called, Policy Deployment) is a key strategic planning to adjust the organization and guarantee that everybody is progressing in the same objectives. The methodology adjusts the need to accomplish day by day gradual improvement while advancing toward the organization's three to five-year advancement targets simultaneously.

6. Kanban

Kanban is a visualizing standard dependent on expanding the progression of goods and work without extra stock or transportation. While at first utilized with physical cards at Toyota, Kanban has now moved to the cloud, and numerous organizations utilize advanced Kanban sheets to follow the progression of work.

7. Problem Solving and Improvement

Despite amazing control, now and then issues will occur, or open doors for development will be recognized. All things considered, at least one of the accompanying Six Sigma instruments can be conveyed.

8. A3 Problem Solving

A3 is an organized critical thinking approach that gets its name from the size of paper that was utilized before digital tools opened up. An A3 report is the consequence of an improvement cycle like DAMIC or PDSA.

9. Catchball

The Six Sigma process of Catchball includes passing ideas starting with one person to others for input and action. The idea (ball) is gotten underway whenever somebody characterizes a test or opportunity.

10. DMAIC

DMAIC is a five-stage improvement cycle; define measure, analyze, improve, control. It carries structure to the improvement process and ensures that each change depends on cautious investigation and valuable data. It begins with the Standard Work and repeats whenever a new opportunity exists.

11. PDSA

PDSA is an optional improvement cycle that represents Plan, Do, Study, Act. It is an easy version of DMAIC that works best for improvement projects that are not heavy on statistics.

12. The 5 Whys

The 5 Whys is a well straightforward strategy for getting to the root of the cause. By asking, "why?" the basis of an issue can usually be found in five iterations.

13. Value Stream Mapping (VSM)

Value Stream Mapping is a Six Sigma apparatus for characterizing and surveying the development of raw materials and work from the earliest starting point of the process to conveyance to the client. It is how the present status of a process is archived, and the reason for figuring out where waste can be dispensed with or esteem included.

This outline doesn't cover each Six Sigma instrument, yet these are the necessities of the tool kit. You may find that you utilize every one of them, or just a couple, however some the combination will probably assist you with accomplishing less variation, and the ability to respond when challenges emerge.

Source: novelvista.com

Wednesday, 18 August 2021

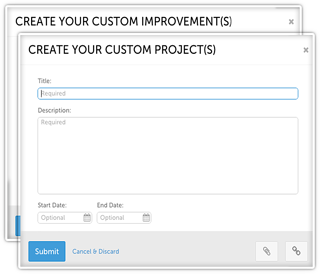

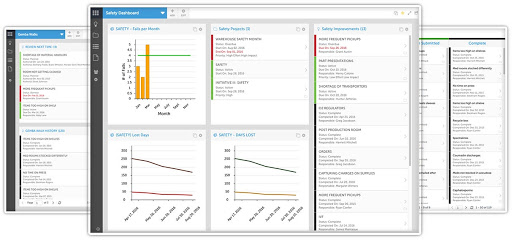

What to Focus on When Picking Six Sigma Software

Read More: Certified Manager of Quality/Organizational Excellence (CMQ/OE)

So, How to pick the right Six Sigma Software:

Capture Opportunities for Improvement

Accelerate Improvement Workflow

Measure Impact

Visual Management

Improvement Broadcasting

Tuesday, 9 March 2021

Comparing and Blending ISO9000 and Lean Six Sigma

During recent decades, a number of different methodologies have evolved to help organizations improve quality, speed and efficiency, and better serve their customers. Manufacturing businesses have concentrated primarily on the ISO system, a series of increasingly tough manufacturing benchmarks and requirements developed by the International Standards Organization, and Lean manufacturing (originally known as the Toyota Production System), which focuses on process speed and the elimination of waste. ISO also has been used in the services arena, although service businesses have been more likely to use various process improvement systems, starting with Total Quality Management in the 1980s and evolving into Six Sigma in the 1990s.

Though each of these methodologies was originally viewed as distinct from the others, businesses are now coming to see that there are valuable synergies between them. Many service organizations, for example, have already begun to blend the higher quality of Six Sigma with the efficiency of Lean into “Lean Six Sigma.” The comparison of Lean Six Sigma to ISO9000 standards and the exploration of how the two can be blended for maximum effect start with a review of both disciplines.

What Is ISO9000?

ISO9000 is a series of international standards that identify the minimum activities that a company must have in place in order to control quality. An ISO9000 Quality Management System is a framework that includes systematic methods, documented processes and defined responsibilities. The system should encompass:

◉ A quality system that describes how the company fulfills the requirements for each element of a given standard.

◉ Practices consistent with documented quality policies and procedures.

◉ Maintenance of quality records.

◉ Performance of regular quality audits.

ISO9000 can serve as a platform for continuous improvement by:

◉ Establishing baselines to measure and evaluate changes and improvements.

◉ Clarifying customer and supplier quality requirements and accountability.

◉ Improving staff understanding of factors in their control that affect quality, and renew commitment to providing quality service.

◉ Facilitating the exchange of technical and practical information both vertically in the hierarchy and peer-to-peer.

◉ Facilitating the training and cross-training through improved documentation.

◉ Increasing effectiveness of internal, customer, supplier and regulatory communications through defined and documented responsibilities and interfaces.

◉ Establishing the means for systematic improvement and renewal through formal corrective/preventative action and internal audits.

What Is Lean Six Sigma?

Lean and Six Sigma is the combination of two tool kits around process improvement that are essential to success in a company. Lean deals with improving the speed of a process by reducing waste and eliminating non-value added steps. Six Sigma improves performance by focusing on those aspects of a process that are critical to quality from the customer perspective and eliminating variation in that process.

Lean utilizes “Kaizen events” – intensive, typically week-long improvement sessions – to quickly identify improvement opportunities and goes one step further than a tradition process map in its use of value stream mapping. Six Sigma uses a formal project methodology known as DMAIC (Define, Measure, Analyze, Improve, Control) to allow project efforts to bring measurable and repeatable results.

Additionally, management engagement and dedicated Champions and Black Belts assure that the prioritized projects are executed as part of a way of doing business. The project benefit matrix process helps identify those most critical projects that will have the largest impact to the bottom-line and can be accomplished the fastest.

Both Lean and Six Sigma are built around the view that businesses are composed of processes that start with customer needs and should end with delighted customers using your product or service.

Adopting a process viewpoint has a profound impact on how an organization operates and how teams view their work. Currently, most companies are organized around functional or “Silo” views: departments and individuals have narrowly defined responsibilities related to specific functions such as accounting, customer service, marketing, etc. Positive change within an organization becomes limited to a defined function and not optimized across an organization. It is not unusual for customer needs to fall between the cracks because no one person owns the process of satisfying the customer. It also is common for many projects to be running at the same time within an organization that sometimes conflict with one another, pull on limited resources, and whose results are not quantifiable in terms of profit and/or customer satisfaction.

In contrast, organizations with process view will assign the Lean Six Sigma resources (Champions, Black Belts, Green Belts, etc.) to map the process across current departmental or functional boundaries. Doing so helps define the interface problems and allows them to propose cross-functional solutions. This process view helps shape decisions and drives project selection based on customer needs, strategic direction, financial requirements and process performance of the company.

Benefits of Lean Six Sigma and ISO9000

The standards, documentation of functional processes, data orientation and passion about quality are all aspects of ISO9000 that fit well with a combined Lean and Six Sigma approach to continuous improvement. Lean Six Sigma would leverage all the standards, documented process, and data already available in your organization. Lean Six Sigma would introduce tools that would help develop process maps with a level of measurable detail that allows identification of non-value-added steps (removal of which will make processes more efficient). It introduces another level of customer focus and a formal methodology (DMAIC) to execute change across functions. It also would engage management and leverage dedicated resources against the projects with the biggest financial impacts to the strategy of the organization. It has been documented that the average Black Belt project saves between $250,000 and $500,000.

These are the additional tools or tactics Lean Six Sigma brings to continuous improvement efforts in an ISO9000 company:

◉ Voice of the Customer as a definition of quality.

◉ Define, Measure, Analyze, Improve, Control (DMAIC) as a structured improvement methodology.

◉ Concept of focus on improving critical process “inputs” rather than just “outputs,” so root causes are attacked and not just symptoms.

◉ CEO and P&L owners are trained and actively engaged in process.

◉ Value-based benefit matrix used to select projects specifically to support strategy and near-term results.

◉ Defined organization and set of roles (Black Belts, Champions, Sponsors) creates accountability for improvement.

◉ Critical mass of resources dedicated to process improvement.

◉ Integration of Lean tools to remove waste and non-value added process complexity/drives speed of delivery (Kaizen events and value stream mapping).

Companies with Both Lean Six Sigma and ISO9000

Many companies who started with ISO9000 have added to it the principals and practices of Lean Six Sigma. The standardization of documentation, mapping of processes, collection of data, auditing of process to assure control and the goal of a quality customer experience are important to both. Together they have many synergies and Lean Six Sigma is a natural step in the evolution of continuous improvement at an ISO 9000 company.

What is the benefit of having dedicated Lean Six Sigma resources and executive support? It is a basic premise of Lean Six Sigma that executive sponsorship is the key to success. Most companies who have built a Lean Six Sigma infrastructure have subsequently rotated the people they’ve trained into leadership positions. That approach makes a lot of sense. For one thing the people chosen to be Black Belts are typically dedicated individuals chosen from the pool of “best and brightest” – i.e., top performers from each line of business (LOB). During their stints as Black Belts, they are placed in positions working for the LOB executives and see the company from a strategic and a day-to-day operational perspective. So they are people who are using their extensive business knowledge and Lean Six Sigma skills and tools to become leaders and facilitators of change. That is why leadership training is a large aspect of the Black Belt certification process. At companies like GE, it is a requirement to be Six Sigma-certified to be considered for a promotion.

Thursday, 22 October 2020

ASQ Six Sigma Certification Preparation Steps and What to Do About Them?

What Is Six Sigma?

The Six Sigma methodology was formed in the mid-1980s by engineers at Motorola to improve manufacturing processes. At its core, Six Sigma includes collecting and leveraging data to reduce defects and waste in manufacturing to improve overall efficiency and quality.

The term sigma is a measure of how far from complete a system or producer can get. By Six Sigma standards, companies should reduce manufacturing defects to less than 3.4 per 1 million units.

Businesses use the Six Sigma methodology to develop processes by identifying the errors that lead to defects and implementing new management systems once mistakes have been addressed. The method is most effective with repetitive, assembly line-style operations where individual steps can be isolated, examined, and improved upon.

Learning Objectives of Six Sigma Certification

Here are the essential learning objectives of ASQ Six Sigma Certification:

- Six Sigma certification helps you to improve your value to your employer and its clients.

- It helps you to improve customer comfort and quality of product and service.

- Reduce the process cycle time and therefore gives overall cost saving up to 30%.

- It helps you to identify and improve requirements in the project definition phase.

- Explain how to measure product and process.

- It helps you to do data analysis and hypothesis testing.

- It provides possible improvement actions for the production of variations.

- They are the right fit to obtain organizational aims.

- You will get higher levels of jobs in the organization.

- This certification training improves your chances of Promotion.

- You can make your current job more comfortable by applying the Six Sigma tools and techniques.

- Overall Business improvement.

How to Get an ASQ Six Sigma Certificate?

To achieve an ASQ Six Sigma certificate, a candidate should meet the experience requirement, give his or her competency for the skill applied, and finally pass a written certification exam.

The written exam is mostly of multiple-choice that progress in assigned time and difficulty at each certification level.

For example, the Yellow Belt exam may take 150 minutes. A Black Belt may take 270 minutes. The hands-on part of the certification examination may require you to complete one or more quality project management with signed affidavits.

Who Needs to Attend Six Sigma Certification?

Some of the professional for whom this training is considered extremely relevant are:

- Quality control professionals

- Process improvement professionals

- Production managers

- Process control specialists

- Frontline and factory supervisors

- Management professionals such as HR

- IT and Finance Engineers

- Business Analysts

Begin Your Preparation for ASQ Six Sigma Certification

To prepare for the Six Sigma Certified exam, make sure that you stick to the given instructions.

Here are the moves that will aid you in the process of preparation:

- The syllabus is the most important part, be it any exam, so make sure you go through the syllabus of the Six Sigma Exam. Prepare your regular study schedule to keep your free time and the time duration until the exam date.

- Every topic of Six Sigma requires to be studied given in the study guide, in-depth.

- Scenario-based logical questions are asked in the Six Sigma exams. Therefore, try to describe every thought with a real-time business scenario while preparing for the exam. Not just will this help you in answering the question better but will also help you expand your knowledge.

Tips and Tricks for Preparation ASQ Six Sigma Certification

- Performing exercises for all the topics will assist you in getting a better grip on the issues.

- Solving exam-oriented ASQ Six Sigma sample questions proves to be of great help. You can find them on ProcessExam.com.

- You can contribute to the practice test for Six Sigma. The questions format will give you an idea of what to assume in your final exam. It will prepare for the real exam as the questions are close to the actual exam, making you feel that you are giving the real exam.

- This will make you know your weak areas at the end of every practice test. Refer to Six Sigma study material for several topics.

- Endeavoring Six Sigma practice tests more and more will aid you to score better than every prior attempt.

- Every practice test you take will take you a move closer to pass the final Six Sigma exam. So make sure you score better every time. This will lead you to your aspired target in the actual exam.

- There are available resources for ASQ Six Sigma Certification Preparation.

How Is Six Sigma Used?

Initially developed for manufacturing, Six Sigma can soon be found across many industries. However, just because companies in various sectors have applied, this methodology does not necessarily mean using it correctly or effectively. Six Sigma often fails to yield the results required to justify such a time-consuming and expensive management change outside of a manufacturing operation.

|

| Read: Six Sigma Certification: Importance, Benefits, And Future |

To function effectively, Six Sigma needs buy-in from everyone involved. It requires a sizable upfront cost to complete and train employees on the methodology of Six Sigma and its performance.

Employees of all levels must be decreased in the different positions of the methodology as well. Individuals who have made a Six Sigma certification class earn belts to designate their group - Green Belts are for boots, Black Belts are for project leaders, and Master Black Belts are for those in charge of achieving Six Sigma the business.

Conclusion

It will become more comfortable for you to crack ASQ Six Sigma certification if the points mentioned above are kept in mind. Always mind it. The more serious you will be regarding your time, the easier it will be for you to utilize it in the right manner.

Wednesday, 3 June 2020

Six Sigma Certification | Career Path | Jobs | Salary

Learning Six Sigma and using its methodologies can have an incredible influence on your future. Being prepared to put Six Sigma certification into your profile gives your promise to improve your business understanding and analytical abilities. Six Sigma certification offers a professional view of the competition.

That can lead to better occupation opportunities and a better salary. Additional design Six Sigma certifications claim so much respect is that they are not easy to achieve.

Obtaining your Six Sigma certification gives you out from the crowd when you are applying for a new job or working on getting a promotion with your modern employer. Six Sigma expertise is in high demand, and hiring managers at companies that have implemented Six Sigma understand the value of certification. They know the commitment it takes to become Six Sigma certified and might not even consider your application if you do not have the credential.

Six Sigma certification shows employers that you understand Six Sigma and that you are committed and motivated. They instantly recognize that you are very knowledgeable in decreasing costs, increasing revenue, improving quality and processes, and gaining employee buy-in.

Six Sigma certification also indicates to employers that you have been trained to be an effective leader. Whether you are a certified yellow belt or black belt, Six Sigma training and certification is all about honing your leadership skills. Employers know that and will compensate you for it.

Job Opportunities for Six Sigma Certified Yellow, Green, and Black Belts

Many companies and government organizations use Six Sigma and need certified yellow belts, green belts, and black belts. Companies like American Express, Boeing, Amazon, and Bank of America have all used Six Sigma to develop methods and business operations.Read: Will a Six Sigma Certification Help Your Career?

Depending on which belt you have and how much experience you have playing in or leading Six Sigma projects, you could get a job in operations, manufacturing, information technology, quality assurance, and more.

According to Six Sigma, The starting point for marketing and sales is not the salespeople; it is the customers. Six Sigma can be used to uncover the best ideas to build and grow relationships with customers in sales. Great relationships are the key to improving sales.

Yellow belts, green belts, and black belts could be applied as Six Sigma consultants, production managers, quality analysts, business analysts, building engineers, process development engineers, project managers, warehouse operations managers, information technology project managers, data scientists, industrial engineers, process development directors, and more. The list continues on and on.

Six Sigma Job Requirements

Keep in mind, and most employers would not even consider a Six Sigma position that needs more than an entry-level understanding of the Six Sigma DMAIC framework without a yellow belt, green belt, or black belt certification.Many employers require candidates to have a point of a bachelor’s qualification in business or another related field. Coursework in project management, statistics, accounting, finance, and business administration are crucial to hiring managers.

From an enterprise’s perspective, attaining a Six Sigma certification enables an individual to become vital. An individual reaches the ability to identify and cut repeatable errors.

With a Six Sigma certification, individuals would be able to transform an organization to increase revenue. You will be able to identify and reduce errors. These errors would have brought poor customer satisfaction and damages to the business. Certified Six Sigma professionals can help decrease complaint resolution time, customer complaints, spending, and cost overruns.

Finally, employers are most involved in candidates who not only have a Six Sigma certification but also have a history of ongoing education, training related to Six Sigma, project management, and continuous improvement.

Salaries for Certified Six Sigma Yellow, Green, and Black Belts

Six Sigma certification is a highly sought-after credential among employers, and they are willing to spend top dollar for job candidates that have yellow, green, and black belts. According to the Salary survey, a Certified Six Sigma Yellow Belt employed in the United States could make from $40,299 to $76,529 per year, depending on the company they work for and where they work.Salary reports that certified Six Sigma green belts can make from $51,280 to $98,381 yearly, and certified Six Sigma black belts salaries vary from $62,214 to $118,134 per year. Depending on how many years of experience you have, which organization you work for, and where you work, your salary could reach even higher.