Often when companies introduce Lean Six Sigma as a way of executing process improvement in its organization, they get excited about all the statistical tools and are enamored with the idea of training Green Belts and Black Belts. An experienced Six Sigma deployment leader will rein-in that enthusiasm and point out that there is much work to be done before candidates are selected for training and statistical software is distributed to the masses.

Companies new to Six Sigma need to build a foundation for repeatable continuous improvement in the organization (infrastructure), as well as an agreed-upon, easily communicated picture of current processes (“as is” state). These are the key elements that give any organization the ability to identify projects that will actually improve processes impacting the customer experience and the ability for change agents to execute improvement in a repeatable and effective fashion.

Capturing the “as is” picture of an organization’s processes is important because it allows a company to be ready for project selection and the introduction of DMAIC (Define, Measure, Analyze, Improve, Control) tools and Six Sigma certification. If done correctly, defining the current state of a company’s processes can help break down strategic focus areas into project ideas. In early Six Sigma deployments, often project scopes are too large, causing excessive project cycle times and loss of internal organizational support. The goal should be ensuring that high-value, well-scoped projects are identified and linked to the company’s strategic objectives. This is the importance of project identification and process mapping: It allows an organization to better understand all the steps, critical inputs and outputs and product and information flows from supplier to customer. Armed with a detailed and shared visual understanding of how work actually occurs, the organization can more easily identify project ideas for improvement.

Once projects are identified, a discussion with key stakeholders can take place to validate initial findings and prioritize projects. This healthy discussion allows individuals to come together and objectively discuss ongoing activities and gaps. Not only will many Lean Six Sigma projects be identified, but other projects that the organization could address will come to light. For the Six Sigma project ideas selected, project charters can be drafted which provide the business case for each project and serves as the guiding framework for improvement efforts. It also is at this point that baseline metrics are established allowing one to track project and process improvement performance.

But it all starts with mapping the current state.

The purpose of mapping an organization’s current process is to position the organization to quickly define, document, analyze, prioritize and recommend solutions and follow-up plans to move the company toward its financial and customer-focused goals. Any process mapping activity starts with a simple assessment that can be conducted by interviewing the key stakeholders of the processes. A key activity for this assessment is capturing those critical-to-quality (CTQ) factors of internal clients’ processes and services to their customers. This lays the foundation for collecting data, developing metrics to measure success, and ultimately building value stream maps.

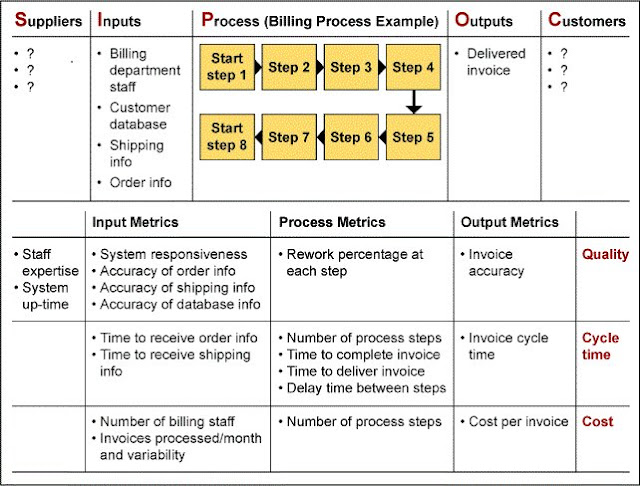

But before a company can leverage the DMAIC process to identify and execute critical process improvement initiatives – let alone do detailed mapping techniques such as value stream mapping – it needs to capture the basics from initial interviews and assessment. This is where one would use a SIPOC diagram; and this initial phase of process mapping is the foundation leveraged throughout the initial phase of a Six Sigma deployment. A SIPOC is a simple process mapping tool used to map the entire chain of events from trigger to delivery of the target process.

SIPOC is an acronym for supplier-input-process-output-customer. A SIPOC diagram helps to identify the process outputs and the customers of those outputs so that the voice of the customer can be captured. When mapping the SIPOC, one can choose the swim lane or unrelated method. The unrelated method requires that the business unit capture all information without directly relating it to a certain process, output, etc. similar to a brainstorming session. This method works best with high-level mapping and is vertical in nature. The swim lane method is best suited for lower detail level mapping. Swim lanes allow the business unit to capture all information directly related to a specific process, output, etc. This method requires more space and several mapping sessions due to the amount of time required to map each process and is horizontal in nature. Basically the documentation used is a combination of matrix, flow chart and summary. And once again includes:

◉ Suppliers: Significant internal/external suppliers to the process.

◉ Inputs: Significant inputs to the process like material, forms, information, etc.

◉ Process: One block representing the entire process.

◉ Outputs: Significant outputs to internal/external customers.

◉ Customers: Significant internal/external customers to the process.

A project team should avoid swim lanes unless if the objective is detailed lower level mapping. This method takes many hours and sessions to complete. Part of the power of the SIPOC is that it is simple to do, but it is full of information that allows the participants in a process to learn together and come to consensus not only about the make-up of the SIPOC itself, but the lessons learned and opportunities as well. Places in the processes for potential improvement can be discussed and prioritized in a non-threatening fashion. By having the business units participate in the session and rank/prioritize opportunities together they tend to be clearer and more descriptive in a shorter period of time. So the SIPOC acts as a dynamic tool to create dialogue and acceptance of a new approach to change in addition to simply capturing the “as is” state.

When creating a SIPOC diagram, a project team does not necessarily begin at the beginning. The team should more likely start in the middle and ask questions about the process itself (P). The team may label the process with the summaries of the most critical three to six steps. Next is documenting what is delivered to whom (O and C). The team can brainstorm and prioritize the most critical one to three customers and identify, prioritize and align the outputs most significant to those customers. Later the team can verify these initial assumptions with voice of the customer tools from the DMAIC process and/or designate as critical to quality, speed or cost. Finally, the team can identify what input or information is needed to perform that process (I) and who provides that input (S). This brainstorming and prioritization of significant inputs finishes the activities around building a SIPOC. Here are some further concepts about building a SIPOC diagram:

◉ Outputs: Outputs are defined as anything the business unit distributes. Frequency/timing is listed along with the output. Examples of outputs would be reports, ratings, products, documents, etc.

◉ Recipients (customers): A recipient is defined as anyone who receives outputs. It is important to note that the recipient must get the output directly from the business unit and does not necessarily have to be a user of the output. If the output is received from a third party, they are not recipients. Examples of recipients would be a manager, CEO, board of directors, another department.

◉ Triggers: Triggers are anything that starts the business unit’s process. A trigger could be the receipt of a report, a certain day of the month, etc.

◉ Estimated Time: The estimated time is how long it takes to complete process steps – this can be continuous, days, weeks, years, etc.

◉ Pain Points: Pain points are ranked/prioritized and then numbered based on the priority.

In the end, the reason a Lean Six Sigma engagement many times begins with building a SIPOC diagram as a first step in the process mapping exercise is threefold in nature:

1. A SIPOC diagram quickly and easily captures the current or “as is” state of the organization and processes in question.

2. The SIPOC exercise brings associates together in a non-threatening way that builds teamwork and momentum to the cause around culture and learning about Six Sigma.

3. The SIPOC exercise allows the team to review all the processes in a manner in which next steps can be identified, and limited resources assigned during the next phase of the roll-out to those processes with an objectively identified listing of the most critical project opportunities.

Companies new to Six Sigma need to build a foundation for repeatable continuous improvement in the organization (infrastructure), as well as an agreed-upon, easily communicated picture of current processes (“as is” state). These are the key elements that give any organization the ability to identify projects that will actually improve processes impacting the customer experience and the ability for change agents to execute improvement in a repeatable and effective fashion.

Capturing the “as is” picture of an organization’s processes is important because it allows a company to be ready for project selection and the introduction of DMAIC (Define, Measure, Analyze, Improve, Control) tools and Six Sigma certification. If done correctly, defining the current state of a company’s processes can help break down strategic focus areas into project ideas. In early Six Sigma deployments, often project scopes are too large, causing excessive project cycle times and loss of internal organizational support. The goal should be ensuring that high-value, well-scoped projects are identified and linked to the company’s strategic objectives. This is the importance of project identification and process mapping: It allows an organization to better understand all the steps, critical inputs and outputs and product and information flows from supplier to customer. Armed with a detailed and shared visual understanding of how work actually occurs, the organization can more easily identify project ideas for improvement.

Once projects are identified, a discussion with key stakeholders can take place to validate initial findings and prioritize projects. This healthy discussion allows individuals to come together and objectively discuss ongoing activities and gaps. Not only will many Lean Six Sigma projects be identified, but other projects that the organization could address will come to light. For the Six Sigma project ideas selected, project charters can be drafted which provide the business case for each project and serves as the guiding framework for improvement efforts. It also is at this point that baseline metrics are established allowing one to track project and process improvement performance.

But it all starts with mapping the current state.

Approach for Process Mapping – SIPOC

The purpose of mapping an organization’s current process is to position the organization to quickly define, document, analyze, prioritize and recommend solutions and follow-up plans to move the company toward its financial and customer-focused goals. Any process mapping activity starts with a simple assessment that can be conducted by interviewing the key stakeholders of the processes. A key activity for this assessment is capturing those critical-to-quality (CTQ) factors of internal clients’ processes and services to their customers. This lays the foundation for collecting data, developing metrics to measure success, and ultimately building value stream maps.

But before a company can leverage the DMAIC process to identify and execute critical process improvement initiatives – let alone do detailed mapping techniques such as value stream mapping – it needs to capture the basics from initial interviews and assessment. This is where one would use a SIPOC diagram; and this initial phase of process mapping is the foundation leveraged throughout the initial phase of a Six Sigma deployment. A SIPOC is a simple process mapping tool used to map the entire chain of events from trigger to delivery of the target process.

SIPOC is an acronym for supplier-input-process-output-customer. A SIPOC diagram helps to identify the process outputs and the customers of those outputs so that the voice of the customer can be captured. When mapping the SIPOC, one can choose the swim lane or unrelated method. The unrelated method requires that the business unit capture all information without directly relating it to a certain process, output, etc. similar to a brainstorming session. This method works best with high-level mapping and is vertical in nature. The swim lane method is best suited for lower detail level mapping. Swim lanes allow the business unit to capture all information directly related to a specific process, output, etc. This method requires more space and several mapping sessions due to the amount of time required to map each process and is horizontal in nature. Basically the documentation used is a combination of matrix, flow chart and summary. And once again includes:

◉ Suppliers: Significant internal/external suppliers to the process.

◉ Inputs: Significant inputs to the process like material, forms, information, etc.

◉ Process: One block representing the entire process.

◉ Outputs: Significant outputs to internal/external customers.

◉ Customers: Significant internal/external customers to the process.

A project team should avoid swim lanes unless if the objective is detailed lower level mapping. This method takes many hours and sessions to complete. Part of the power of the SIPOC is that it is simple to do, but it is full of information that allows the participants in a process to learn together and come to consensus not only about the make-up of the SIPOC itself, but the lessons learned and opportunities as well. Places in the processes for potential improvement can be discussed and prioritized in a non-threatening fashion. By having the business units participate in the session and rank/prioritize opportunities together they tend to be clearer and more descriptive in a shorter period of time. So the SIPOC acts as a dynamic tool to create dialogue and acceptance of a new approach to change in addition to simply capturing the “as is” state.

Building a SIPOC Diagram

When creating a SIPOC diagram, a project team does not necessarily begin at the beginning. The team should more likely start in the middle and ask questions about the process itself (P). The team may label the process with the summaries of the most critical three to six steps. Next is documenting what is delivered to whom (O and C). The team can brainstorm and prioritize the most critical one to three customers and identify, prioritize and align the outputs most significant to those customers. Later the team can verify these initial assumptions with voice of the customer tools from the DMAIC process and/or designate as critical to quality, speed or cost. Finally, the team can identify what input or information is needed to perform that process (I) and who provides that input (S). This brainstorming and prioritization of significant inputs finishes the activities around building a SIPOC. Here are some further concepts about building a SIPOC diagram:

◉ Outputs: Outputs are defined as anything the business unit distributes. Frequency/timing is listed along with the output. Examples of outputs would be reports, ratings, products, documents, etc.

◉ Recipients (customers): A recipient is defined as anyone who receives outputs. It is important to note that the recipient must get the output directly from the business unit and does not necessarily have to be a user of the output. If the output is received from a third party, they are not recipients. Examples of recipients would be a manager, CEO, board of directors, another department.

◉ Triggers: Triggers are anything that starts the business unit’s process. A trigger could be the receipt of a report, a certain day of the month, etc.

◉ Estimated Time: The estimated time is how long it takes to complete process steps – this can be continuous, days, weeks, years, etc.

◉ Pain Points: Pain points are ranked/prioritized and then numbered based on the priority.

1. A SIPOC diagram quickly and easily captures the current or “as is” state of the organization and processes in question.

2. The SIPOC exercise brings associates together in a non-threatening way that builds teamwork and momentum to the cause around culture and learning about Six Sigma.

3. The SIPOC exercise allows the team to review all the processes in a manner in which next steps can be identified, and limited resources assigned during the next phase of the roll-out to those processes with an objectively identified listing of the most critical project opportunities.