The food industry constantly evolves, with new trends and technologies emerging daily. However, one thing that remains a constant priority is the quality and safety of food products. Many food companies have turned to Six Sigma and quality control practices to achieve this. Six Sigma is a data-driven approach to improving processes and reducing defects, while quality control ensures that products meet certain standards of quality. In this blog, we will take a closer look at how Six Sigma and quality control can be applied in the food industry to ensure that products are safe, high-quality, and meet the needs of consumers. We will also discuss the specific challenges and considerations that the food industry faces when implementing Six Sigma and quality control and how to overcome them. Finally, this blog will explore how Six Sigma and quality control can help the food industry create a safer, more efficient, and more satisfying customer experience.

Six Sigma in the Food Industry

“Six Sigma in the Food Industry” refers to applying the Six Sigma methodology to the processes and operations of food companies. Six Sigma is a data-driven approach to process improvement that aims to reduce defects and increase efficiency. Companies in various industries, including healthcare, service, and manufacturing, have widely adopted it. It can be adapted and expanded to include other approaches such as “Lean Six Sigma,” which combines Six Sigma methodology with Lean Manufacturing principles.

In the food industry, Six Sigma can be used to improve the quality and safety of food products, increase efficiency and reduce costs. The food industry is a highly regulated sector, and food companies must comply with strict laws and regulations to ensure the safety and quality of their products. Six Sigma can help food companies to meet these regulations by identifying and eliminating sources of defects and inefficiencies.

How is Six Sigma Applied in the Food Industry?

Six Sigma can be applied in the food industry in various ways, depending on the specific needs and goals of the company. Some of the key ways in which Six Sigma is applied in the food industry include:

Identifying and Eliminating Sources of Food Contamination

One of the key benefits of Six Sigma in the food industry is that it can help companies to identify and eliminate sources of food contamination. By using Six Sigma tools such as cause and effect diagrams, flowcharts, and statistical process control, companies can identify the key variables affecting the process and eliminate them.

Improving Process Efficiency

Six Sigma can also help food companies improve their operations’ efficiency by identifying and eliminating bottlenecks and reducing waste. This can be done using Six Sigma tools such as process mapping, value stream mapping, and flowcharts to identify inefficiencies and bottlenecks in the process.

Creating a Culture of Quality and Safety

Another important aspect of Six Sigma in the food industry is the critical importance of a culture of quality and safety. Six Sigma can create a culture of quality and safety by involving employees at all levels in the process improvement initiative and promoting continuous improvement. By creating a culture of quality and safety, companies can ensure that the improvements made to their processes are sustained over time.

Improving Customer Experience

In addition to these benefits, Six Sigma can also improve the customer experience in the food industry by ensuring that food products are high-quality and safe to eat. Six Sigma can also help food companies to reduce costs by reducing defects and improving efficiency.

Compliance with Regulations

The food industry is a highly regulated sector, and food companies must comply with strict laws and regulations to ensure the safety and quality of their products. Six Sigma can help food companies to meet these regulations by identifying and eliminating sources of defects and inefficiencies.

Supply Chain Management

Six Sigma can also be applied to supply chain management in the food industry to ensure that suppliers are meeting quality standards and improving the supply chain’s efficiency. This can be done using Six Sigma tools such as statistical process control, cause and effect diagrams, and flowcharts.

In conclusion, Six Sigma can be applied in the food industry in various ways to improve the quality and safety of food products, increase efficiency and reduce costs, create a culture of quality and safety, improve the customer experience, and ensure compliance with regulations.

Benefits of Implementing Six Sigma in the Food Industry

Implementing Six Sigma in the food industry can bring a variety of benefits to companies in this sector, including:

Improved Food Safety

By implementing Six Sigma in the food industry, companies can improve the safety of their food products by identifying and eliminating sources of food contamination. Six Sigma methodologies such as statistical process control, cause and effect diagrams, and flowcharts can be used to identify key variables that are affecting the process and take steps to eliminate them. This can help to reduce the risk of foodborne illness and protect the company’s reputation.

Increased Efficiency

Six Sigma can also help food companies to increase efficiency by identifying and eliminating bottlenecks and reducing waste in their operations. By using Six Sigma tools such as process mapping, value stream mapping, and flowcharts, companies can identify inefficiencies and bottlenecks in the process and take steps to eliminate them. This can help companies to save money by reducing costs and improving their bottom line.

Better Quality Control

Six Sigma can also help food companies improve their products’ quality by reducing defects and ensuring that products meet customer requirements. Six Sigma methodologies such as statistical process control, design of experiments, and process capability analysis can be used to monitor and control quality in the food industry. This can help companies to improve customer satisfaction and increase repeat business.

Cost Savings

Implementing Six Sigma in the food industry can also help companies save money by reducing waste, defects, and rework costs. By identifying and eliminating sources of inefficiency, companies can reduce their overall costs and improve their bottom line.

Compliance with Regulations

Food companies must comply with strict laws and regulations to ensure the safety and quality of their products. Six Sigma can help food companies to meet these regulations by identifying and eliminating sources of defects and inefficiencies. This can help companies to avoid costly fines and penalties associated with non-compliance.

Employee Empowerment

Six Sigma encourages employees at all levels of an organization to participate in the process improvement initiative. This can create a culture of quality and safety and empower employees to take an active role in improving the processes they work with.

Improved Customer Experience

By implementing Six Sigma in the food industry, companies can ensure that their products are high-quality and safe. This can help to improve customer satisfaction and increase repeat business.

In summary, implementing Six Sigma in the food industry can bring various benefits to companies in this sector, including improved food safety, increased efficiency, better quality control, cost savings, compliance with regulations, employee empowerment, and improved customer experience.

Examples of Six Sigma in the Food Industry

The following are some examples of the companies that have implemented six Sigma:

McDonald’s

McDonald’s has implemented Six Sigma to improve the efficiency and quality of its food preparation process. The fast-food giant uses Six Sigma methodologies to streamline operations, ensuring food is prepared quickly and consistently. By using Six Sigma tools such as process mapping, statistical process control, and the design of experiments, McDonald’s was able to identify and eliminate bottlenecks in its operations, resulting in faster service times and improved food quality.

Nestle

Nestle, a leading food and beverage company, uses Six Sigma to improve the quality and safety of its products. By using Six Sigma methodologies, Nestle can identify and eliminate sources of food contamination, ensuring that its products are safe to consume. The company also uses Six Sigma tools such as statistical process control and the design of experiments to monitor and control the quality of its food products, resulting in improved quality and customer satisfaction.

Coca-Cola

Coca-Cola, a leading beverage company, uses Six Sigma to improve the efficiency and quality of its operations. By using Six Sigma methodologies such as process mapping, statistical process control, and the design of experiments, Coca-Cola was able to identify and eliminate bottlenecks in its operations, resulting in improved efficiency and cost savings. The company also uses Six Sigma tools to monitor and control the quality of its products, resulting in improved quality and customer satisfaction.

These are examples of how Six Sigma is implemented in the food industry. As a result, these companies have been able to realize significant improvements in the efficiency and quality of their operations and products, resulting in cost savings and improved customer satisfaction.

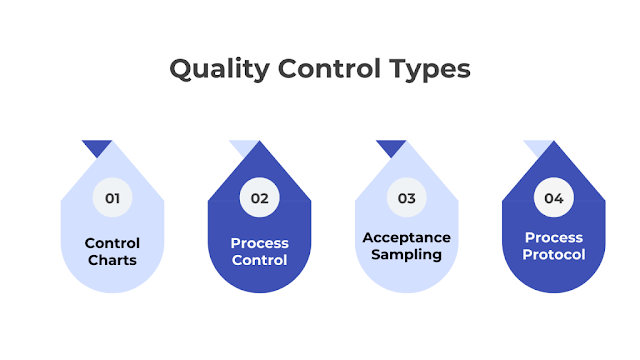

What is Quality Control?

Quality control (QC) ensures that a product or service meets a certain set of quality standards. It involves inspecting, testing, and measuring products and services to ensure they meet the desired specifications. Quality control aims to identify and prevent defects or nonconformities in a product or service before it reaches the customer.

Quality control is often divided into two main categories: incoming quality control and outgoing quality control. Incoming quality control (IQC) is inspecting and testing raw materials and components before they are used in production. Outgoing quality control (OQC) inspects and tests finished products before they are shipped to customers.

Importance of Quality Control in the Food Industry

Quality control is paramount in the food industry as it ensures food products’ safety, compliance, and overall quality. The food industry is heavily regulated, and non-compliance with safety standards can lead to legal and financial consequences and damage to a company’s reputation. Quality control ensures that food products meet safety standards and regulations and are free from contaminants and other harmful substances.

Food quality is also an important factor in the food industry. Quality control ensures that food products are consistent in taste, appearance, and texture and meet consumers’ expectations. This helps to maintain customer loyalty and repeat business.

Quality control also helps to minimize food waste and improve efficiency in the food industry. By identifying and eliminating sources of variability and defects in food products, quality control can help to reduce waste, increase efficiency, and save money.

In summary, quality control is essential in the food industry to ensure the safety and compliance of food products, maintain customer satisfaction and loyalty, and improve efficiency. In addition, a good quality control program can help ensure that food products meet or exceed customer expectations and help maintain the company’s reputation in the industry.

Different Quality Control Techniques used in the Food Industry

Listed below are the Quality Control Methods utilized in the Food Industry:

Hazard Analysis and Critical Control Points (HACCP)

This is a systematic method used to identify and control potential food production and processing hazards. HACCP involves:

◉ Analyzing the entire food production process

◉ Identifying potential hazards

◉ Implementing controls to minimize the risk of these hazards

The seven principles of HACCP are:

◉ Conducting a hazard analysis

◉ Determining the critical control points

◉ Establishing critical limits

◉ Implementing monitoring procedures

◉ Implementing corrective actions

◉ Implementing verification procedures

◉ Maintaining records and documentation

Statistical Process Control (SPC)

This technique uses statistical methods to monitor and control production processes. SPC involves:

◉ Collecting data on key process variables

◉ Analyzing the data

◉ Using this information to identify and control sources of variability and defects

The data is plotted on control charts which helps to identify if the process is in or out of control.

Good Manufacturing Practices (GMP)

GMP is a set of guidelines that provide a framework for maintaining cleanliness and hygiene in food production and processing. GMP includes personnel hygiene, sanitation, equipment maintenance, and record-keeping guidelines. This can be used to ensure that the food production process complies with food safety regulations and that food products are free from contaminants and safe to consume.

Internal Auditing

This technique involves regular audits of the food production process to ensure compliance with quality standards and regulations. Audits may include inspections of facilities, equipment, and records, as well as sampling and testing food products. These audits are conducted by the internal team or external auditors to check the facility’s compliance and to identify any areas of improvement.

Sensory Analysis

This technique involves evaluating the quality of food products through the senses of taste, smell, and appearance. Sensory analysis can be used to identify defects and variations in food products and to develop quality standards. This is done by a panel of trained testers who evaluate the product against a set of predefined attributes.

Microbiological Testing

This technique involves testing food products for the presence of harmful microorganisms. Microbiological testing can detect bacteria, viruses, and other microorganisms that may be present in food products and can cause food poisoning. This is done by collecting food product samples and sending them to a lab for testing. The test results are then used to determine if the food product is safe to consume.

How Do Six Sigma and Quality Control Work Together?

Six Sigma and Quality Control are two methodologies that work together to improve the quality of products and processes in an organization. Six Sigma is a data-driven, problem-solving methodology used to identify and eliminate defects in a process. Six Sigma uses statistical tools and techniques to identify the sources of variability and defects in a process and to develop and implement solutions to improve the process. Quality Control, on the other hand, is a set of practices and techniques used to ensure that products and processes meet specified quality standards. Quality Control includes inspections, testing, and monitoring to ensure that products and processes are free from defects and meet customer requirements.

When Six Sigma and Quality Control are used together, they provide a comprehensive approach to quality improvement. Six Sigma is used to identify and eliminate the root causes of defects, while Quality Control is used to ensure that the process is in control and that the product meets quality standards. This helps to ensure that the process is efficient and effective and that the final product is high quality.

For example, Six Sigma can identify and eliminate the sources of variability in a food production process, and quality control can ensure that the food products produced by the process meet specified quality standards.

Together, Six Sigma and Quality Control provide a powerful toolset for improving the quality of products and processes and for ensuring that customer requirements are met. As a result, it helps organizations increase customer satisfaction, reduce costs, and improve efficiency.

Advantages of Combining Six Sigma and Quality Control

Combining Six Sigma and Quality Control methodologies can provide several advantages for organizations, including:

Improved Efficiency

Six Sigma focuses on identifying and eliminating the root causes of defects and variability in a process. In contrast, Quality Control focuses on ensuring that the process is in control and that the product meets quality standards. By combining these methodologies, organizations can improve the efficiency of their processes and produce higher-quality products.

Cost Savings

Six Sigma helps organizations to identify and eliminate waste in their processes, which can lead to significant cost savings. Quality Control, on the other hand, helps to ensure that products and processes meet quality standards, which can reduce the costs associated with defects and rework.

Increased Customer Satisfaction

Six Sigma and Quality Control work together to improve the quality of products and processes, which can lead to increased customer satisfaction. Organizations implementing these methodologies can expect improved customer satisfaction, increased repeat business, and improved brand reputation.

Improved Employee Engagement

Six Sigma and Quality Control involve significant employee engagement, which can lead to improved employee morale and motivation. By involving employees in identifying and solving problems, organizations can create a culture of continuous improvement that can lead to improved performance and increased job satisfaction.

Better Data Analysis

Six Sigma methodologies use statistical tools and techniques to identify the sources of variability and defects in a process. Quality Control also uses various techniques to evaluate the quality of the product. Together, these methodologies can provide comprehensive data analysis, resulting in more accurate and effective solutions to quality problems.

Improved Compliance

The food industry has to comply with various regulations and standards. By combining Six Sigma and Quality Control, organizations can ensure that their products and processes meet these standards and regulations, which can reduce the risk of non-compliance and associated penalties.

In summary, combining Six Sigma and Quality Control methodologies can provide a powerful toolset for improving the quality of products and processes, reducing costs, and increasing customer satisfaction. It can also help organizations comply with regulations and standards, which is important in the food industry. It also creates a culture of continuous improvement and better employee engagement.

Implementing Six Sigma and Quality Control in the Food Industry

Implementing Six Sigma and Quality Control in the Food Industry can be complex. Still, it can also be extremely beneficial for organizations looking to improve the quality of their products and processes. Here are the steps that organizations can take to implement these methodologies:

Define the Problem

The first step in implementing Six Sigma and Quality Control is to define the problem that needs to be solved. Food industry organizations often need help with various quality-related issues, such as variability in product quality, high levels of waste, and non-compliance with regulations and standards. Therefore, organizations should take the time to identify the specific problem areas they need to address.

Measure the Current Performance

Once the problem has been defined, organizations should measure their current performance to establish a baseline. This can be done using various tools, such as control charts, statistical process control, and process mapping. In addition, organizations should collect data on the key quality characteristics of their products, as well as on the performance of their processes.

Analyze the Data

The next step is to analyze the data that has been collected. Organizations should use statistical tools and techniques to identify their processes’ sources of variability and defects. This can include tools such as Pareto charts, cause and effect diagrams, and hypothesis testing.

Improve the Process

Once the problem has been identified and analyzed, organizations should develop and implement solutions to improve their processes. This can include changes to the product design, process changes, and how employees work. Organizations should also develop a plan for monitoring and controlling the process to ensure that the improvements are sustained.

Implement Quality Control

Quality Control is an ongoing process that should be integrated into the overall management system. Organizations should establish quality standards and procedures and implement inspection and testing procedures to ensure that products meet these standards. Organizations should also establish a system for recording and analyzing quality data and taking corrective action when necessary.

Monitor and Control the Process

Once the process has been improved, organizations should monitor and control it to ensure that the improvements are sustained. This can be done using various tools, such as control charts, statistical process control, and process mapping. Organizations should also establish a system for recording and analyzing data on the performance of the process.

Continual Improvement

Six Sigma and Quality Control are continuous improvement methodologies, so organizations should always look for ways to improve their products and processes. This can be done by regularly reviewing the data that has been collected, conducting root cause analysis, and implementing new solutions.

In summary, implementing Six Sigma and Quality Control in the food industry requires a comprehensive and ongoing effort to identify, analyze, and solve quality-related problems. It involves defining the problem, measuring the current performance, analyzing the data, improving the process, implementing quality control, monitoring and controlling the process, and continually improving. It is a continuous improvement process that requires commitment from all levels of the organization.

Future of Six Sigma and Quality Control in the Food Industry

The future of Six Sigma and Quality Control in the Food Industry looks promising as more and more companies realize the benefits of implementing these methodologies. Furthermore, implementing Six Sigma and Quality Control will become even more important with the increasing demand for high-quality food products and the need to comply with strict regulatory requirements.

One of the key trends in the future is integrating technology into Six Sigma and Quality Control processes. For example, data analytics and artificial intelligence (AI) will help companies collect and analyze large amounts of data, identify patterns and trends, and make more informed decisions. This will lead to a more efficient and effective implementation of Six Sigma and Quality Control methodologies.

Another trend is the focus on sustainability and environmental responsibility. Companies will need to implement Six Sigma and Quality Control practices that not only ensure the quality of their products but also positively impact the environment. This may include initiatives such as reducing waste and energy consumption and implementing sustainable sourcing practices.

In addition, the increasing global competition in the food industry will drive companies to implement Six Sigma and Quality Control to maintain a competitive edge. The ability to produce high-quality products consistently and efficiently will be a key differentiator for companies in the future.

In conclusion, Six Sigma and Quality Control methodologies will continue to play a critical role in the Food Industry as companies strive to produce high-quality products, comply with regulations, and meet consumer demands. Furthermore, the future of Six Sigma and Quality Control in the Food Industry looks promising as new technologies and sustainability initiatives are integrated, and companies focus on staying competitive in the global market.

Source: invensislearning.com