In the cooperative world, it has been been most speculated and debated issue and today’s too, that which methodology would be more productive and efficient for organizations. It would we ex-aggregation if I declared that specific one model is more vibrant in comparison to others. Because we can’t undermine capability of any one of them. The methodology that enterprise chooses strictly depends on shape, size, and function or projects they do. And different organizations have their different needs to achieve goals and to full-fill these needs they opt methodology that suited them most.

Here we’ll see differences between both and that may help you to go with best one for your organization.

Lean and Six Sigma has common motive :

Both wants to eliminate waste and increase productivity & efficiency of organizational

operations but methodology to beat goal of both model is distinct (means they identify root cause of problem in different manner).

1. Six Sigma Model :

Six Sigma was developed for a very specific goal to achieve, It includes an special approach to handle the organizational challenges by reduce the variation, risks, waste and defect rates in production processes through the well organized statistical method of analysis. To do this, Six Sigma uses one of two the approaches – either the DMAIC or the DMADV method.

Here DMAIC stands for Define, Measure, Analyze, Improve, and Control while DMADV stands for Define, Measure, Analyze, Design, Verify. DMAIC is mostly used method which we’re explaining here.

DMAIC :

1. Define –

In the first step, you will define problem and how it is disturbing current process.

2. Measure –

During this step, you will measure current data. By examining process that is already in place and identifying what isn’t working you can begin finding ways to make improvements.

3. Analysis –

Now after collecting concerned data, you start analyzing to get to root cause of problem.

4. Improvement –

This is the step where you will come up with possible solutions, test your solutions, and applies which suited best.

5. Control –

Once you have implemented new process you must continue to make improvements over time in searching of most favorable solution. These changes will only last if employees continue to refine and maintain process.

Here, are some certifications of Six Sigma :

1. Black Belt –

Leads problem-solving projects. Trains and coaches project teams.

2. Green Belt –

Assists with data collection and analysis for Black Belt projects. Leads Green Belt projects or teams.

3. Master Black Belt –

Trains and coaches Black Belts and Green Belts. Functions more at Six Sigma program level by developing key metrics and strategic direction. Acts as organization’s Six Sigma technologist and internal consultant.

4. Yellow Belt –

Participates as project team member. Reviews process improvements that support project.

5. White Belt –

Can work on local problem-solving teams that support overall projects, but may not be part of Six Sigma project team. Understands basic Six Sigma concepts from awareness perspective.

Six Sigma is majorly applied in various fields like functional areas, such as engineering, manufacturing, plant operations, planning as well as sales/marketing and customer support service, but it’s not suitable for small enterprises projects or process.

Because many small companies can not afford resources that this model requires. Six Sigma deployed at each and every level within organization, with distinct roles and responsibilities these roles and responsibilities are borne by concerned employees.

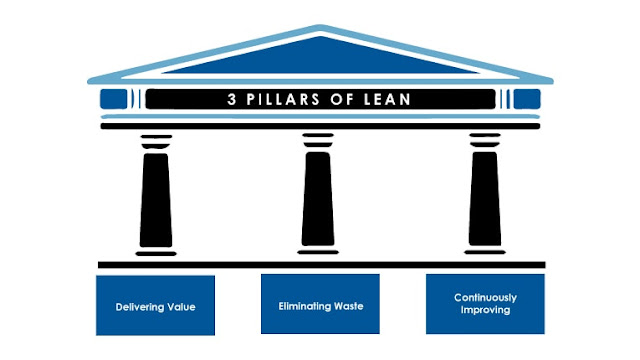

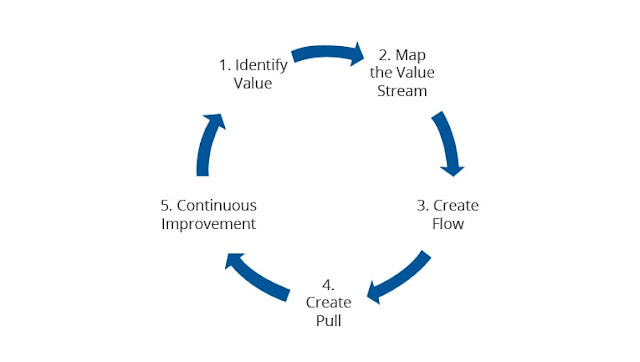

2. Lean Model :

Lean method, is completely focused on eliminating waste by eliminating bottlenecks and improving quality of your products providing maximum profit value to customers with lowest possible amount of investment and risks. The term Lean was first coined by Toyota to describe Toyota Business System in 1980’s, business philosophy that helped company run at maximum efficiency. Prime motive of Lean model is Customer satisfaction.

If we use DMAIC method with principle of Lean model then it’ll give more favorable output.

Lean identifies deadly areas of waste that are common in most production systems :

1. Defects –

Products that don’t meet quality standards.

2. Overproduction –

Exceeding demand or producing more than was ordered.

3. Waiting –

Waiting is lag time in between each step in production. When employees are left waiting no value is being added.

4. Non-Utilized Talent –

Ineffectively using or miscalculating human resources.

5. Transportation –

Inefficient shipping methods.

6. Inventory –

Holding on to surplus of product or raw material.

7. Motion –

Unnecessary moving of product, material, or people.

8. Extra Processing –

Doing more work than is needed in very inefficient manner.

Differences between Six Sigma and Lean :

| Six Sigma | Lean |

| Focuses on reducing variation, risks, waste and defects. | Focuses on eliminating waste by eliminating bottlenecks. |

| Improves quality of products, performance & services. | Improves flow. |

| Reduce variation at each remaining steps. | Remove non-value added process steps. |

| Improves Accuracy. | Improves speed of processes. |

| Customer-centric. | Customer-centric. |