With Lean management, you can have all three.

At its core, the philosophy of Lean management is to maximize customer value while minimizing waste. It is one of the most popular management systems and for good reason – no matter which industry you are in, Lean is a universal tool that can have a positive impact on any company’s performance.

It is not just a quick business hack – it is an entire business philosophy that has been around for decades and can have dramatic impacts on your business, from top to bottom.

In short, it can radically improve your business.

What Is Lean Management?

The foundations of Lean management, often shortened to just Lean, are built upon removing processes that do not bring value to the end product.

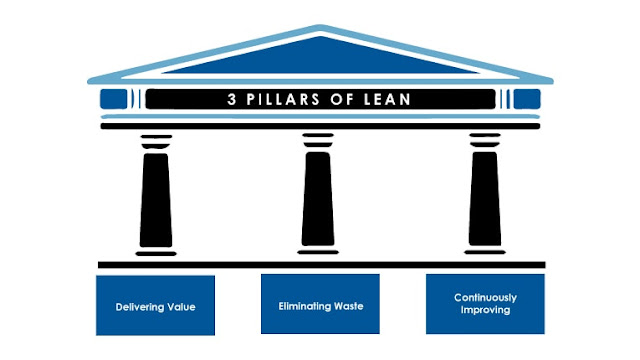

This is best described in the three key pillars of Lean (Figure 1):

1. Delivering value from your customers’ perspective

2. Eliminating waste (again, from your customers’ perspective)

3. Continuously improving your processes to better serve customers

Figure 1: 3 Pillars of Lean Management

While they sound simple, these three key pillars of Lean strategy can have staggering results in improving efficiency, productivity and time management. By stripping away everything that does not bring value to the final product or service, you create a business that is 100 percent efficient with absolutely no wastage.

The Roots of Lean

Lean was not born in a classroom. In fact, lean originally comes from the car company Toyota, where Lean was coined to describe the unique business model used by this uber-successful car manufacturing giant. The Lean movement is therefore often referred to as the Toyota Way because it derived from the Toyota Production System.

Leading the team who shared this with the world was Dr. James Womack, who went to Japan. Together with Daniel Jones he wrote The Machine That Changed the World and later with Jones and Daniel Roos, Womack wrote another book about the Toyota Way called Lean Thinking. Both books remain a centerpiece of Lean management education to this day.

Inspired by Toyota’s methodologies, Lean provides a comprehensive framework to help business owners answer the types of questions that matter the most, no matter what stage their business is at. Knowing where best to invest time or money can be critical for future performance: should I invest in new equipment, hire new people or make my staff work longer hours?

The answer lies in shorter lead times, higher quality and lower costs. And Lean management shows us that all that are possible.

While owners often think, “How can I grow my business faster?” under Lean, the real question is: “How I can provide more value to my customer?”

The Four Principles of Lean

To get a good idea of how Lean works, this video from Four Principles shows us more about this revolutionary management style.

As the video highlights, there are four central ideologies at the heart of Lean management:

◈ Pull: Rather than produce as much as possible, customer demand “pulls” goods and services through the manufacturing process, minimizing production, inventory and working capital.

◈ One-piece flow: Focusing on one piece at a time minimizes work in progress, process interruptions as well as lead and wait times, all while increasing quality and flexibility.

◈ Takt: Takt is the heartbeat of a Lean system and is defined as the speed at which you need to manufacture a product in order to meet demand. Takt allows us to balance work content, achieve a continuous flow and respond flexibly to changes in the market place

◈ Zero defects: Mistakes happen, but a Lean company does not pass on defects. Mistakes from previous steps must be corrected before going on.

With these four principles, companies can respond quickly to changing consumer demands at very little cost; with no inventory, a massive shift in product type or service offering will not be a problem for Lean companies. The principles of pull, one-piece flow, takt and zero defects will help your company to stay ahead of the competition in a constantly changing marketplace.

The final piece to the Lean puzzle is vitally important and is the glue that holds the whole system together: continuous improvement.

5 Steps to Lean

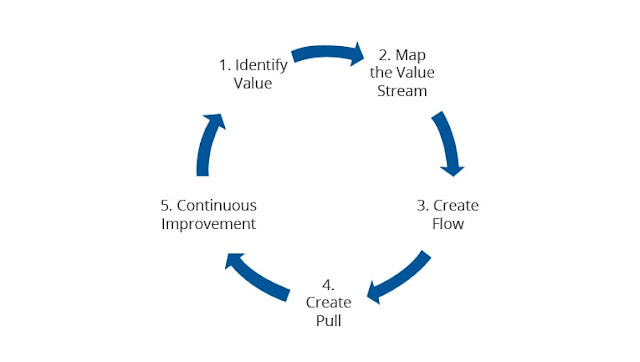

Implementing Lean can be tricky. To help, there are five basic steps to achieve maximum efficiency, which can be summarized in the Lean improvement cycle (Figure 2).

Figure 2: Five Steps of Lean Management

1. Identify value: The first step in Lean implementation is to identify value from the standpoint of the end customer. To do this, you need to understand what drives sales. What is it that makes your company so good? What value are consumers getting from your company?

2. Value stream mapping: The second step involves mapping out all the steps for each individual product or service. This includes all the actions your business takes to deliver the identified value to your customer.

3. Create one-piece flow: Now you’ve mapped out your value stream, what improvements can be made? Identify steps that do not create value and if you can, eliminate them. If you can’t eliminate, improve them. Make the value-creating steps occur in a tight sequence so the product flows smoothly to the customer in the fewest number of steps. Make it impossible to pass on defects down the chain.

4. Create pull: As flow is introduced, let customers pull value from the next upstream activity so that work is done only if there is a need for it. This step is key in eliminating waste – both resources and time.

5. Continuous improvement: After one run through of this process it is vital that you go back to the beginning and repeat this same process, again and again. Once flow and pull have been created, begin the cycle again and again, until you reach a state of perfection where every step in the process provides maximum value.

Over time, this continual refinement of production processes will eliminate bottlenecks and interruptions, increasing production speed without sacrificing quality. Information management becomes simpler and problems are more easily removed. Smoothing the process will remove any unwanted waste while giving employees a sense of value.

It is important that every employee feels valuable because you need to ensure that this process works from the ground up. That includes everyone from the receptionist right up to the CEO. By having a tight process line it is clear what everyone is working on and why.

There are various ways you can encourage this type of behavior at your workplace such as daily review sessions and rewards. The idea is to produce a stable production system where every step of the way creates value. This can only be achieved through continuous effort and improvement.

How Can Lean Benefit My Business?

While Lean seems particularly well suited to manufacturing type companies like Toyota, it doesn’t matter what type of business you run. Lean is a universal management tool that can have a positive impact on any company’s performance, whether you run a PR company, produce high-tech software or run a service business in the healthcare industry.

Lean focuses on the entire business – not just the manufacturing of a product – so it does not matter whether your business has a physical product or not. Unlike other management systems, Lean improves the entire value stream and not just an isolated point in the chain, which makes it easily replicable between business types.

For example, Lean has been instrumental for computing leader Intel to stay ahead of the competitive curve: In 2014, Joe Foley, factory manager at Intel Fab Operations in Ireland, said: “Five years ago, it took us 14 weeks to introduce a new chip to our factory; now it takes 10 days. We were the first Intel factory to achieve these times using Lean principles.”

At Seattle-based healthcare provider Virginia Mason, basic tenants of the Toyota Production System combined with elements of Kaizen and Lean in 2002 to create a unique version of Lean called the Virginia Mason Production System, which is focused on improving patient safety and quality. Erica Cumbee, a faculty member at Virginia Mason Institute, said: “Focusing on the highest quality and safety means pursuing zero defects in health care by removing waste and designing mistake-proofed processes. The tools of the Virginia Mason Production System support this work, but it is the culture that sustains it.”

For John Deere, the agricultural machinery expert, it is a similar story: In 2003 John Deere spent $100 million on transforming its business model using Lean principles. Project manager Kallin Kurtz said: “This project transformed our manufacturing engineering mindset. We have put a great deal of effort into identifying non-value-added activities and eliminating them where possible.”

Transformation Through Lean

Implementing Lean requires a long-term perspective. It won’t happen overnight but can be achieved by a rigorous feedback cycle of constant improvement. The goal is to reach zero waste in the company and thus achieve maximum customer value.

By using the five-step improvement process to implement the key principles of Lean, you can encourage your business to work smarter, not harder. The methodology of Lean focuses on creating value at every level, which builds overall value for your company and when done correctly, can be transformational.

Through Lean, it is possible to have better products, made in a shorter time and at lower costs. It will take time but you must continuously work to improve to bring you closer to your Lean goal. Have trust in everyone throughout your organization and over time, your chances for success will rapidly increase.

0 comments:

Post a Comment