Sometimes it is easy to get into a rut when it comes to doing analysis. It can be hard to stray from those same time-tested analytical tools used in the Six Sigma methodology. The process map, failure modes and effects analysis, cause-and-effect matrix, and fishbone diagram are like well used tools that feel comfortable and are relatively easy to use.

However, there is an analytical tool that is seldom used in Six Sigma but is very valuable. The tool, the causal loop diagram (CLD), is a foundational tool used in system dynamics, a method of analysis used to develop an understanding of complex systems. Dr. Jay Forrester of MIT’s Sloan School of Management founded system dynamics in the 1950s and his book Industrial Dynamics was groundbreaking. Thirty years later, Peter Senge in his book The Fifth Discipline covered in detail systems thinking, another unique discipline, using the CLD as its centerpiece.

So the question is: How does CLD apply to Six Sigma? Quite simply, it is the causal loop diagram’s unique ability to identify and visually display intricate processes and root causes. Every system behaves in a particular manner due to the influences on it. Some of these influences can be changed, some cannot, and some can minimized. Causal loop diagrams bring out the systematic feedback in processes by showing how variable X affects variable Y and, in turn, how variable Y affects variable Z through a chain of causes and effects. By looking at the all the interactions of the variables, the behavior of the entire system is discovered. With a CLD, a practitioner no longer needs to focus only on one interaction between two variables, but can focus on the entire system, along with its many variables and its many causes and effects. Only through this thorough analysis can a Six Sigma Black Belt or an organization make changes that are lasting in nature.

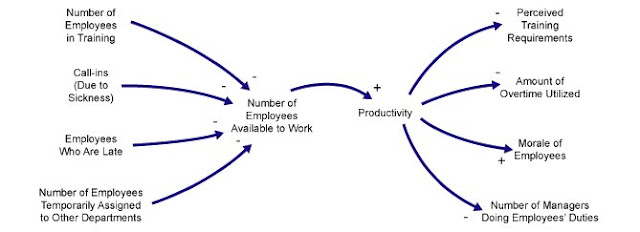

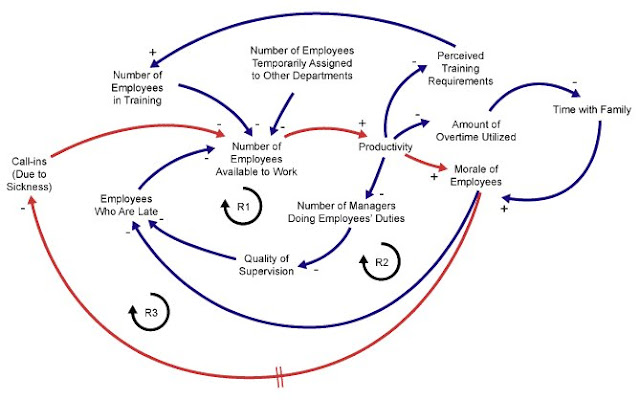

First, it is important to understand the structure used to create a causal loop diagram. CLDs consist of arrows connecting variables that show how one variable affects and impacts another variable (Figure 1).

However, there is an analytical tool that is seldom used in Six Sigma but is very valuable. The tool, the causal loop diagram (CLD), is a foundational tool used in system dynamics, a method of analysis used to develop an understanding of complex systems. Dr. Jay Forrester of MIT’s Sloan School of Management founded system dynamics in the 1950s and his book Industrial Dynamics was groundbreaking. Thirty years later, Peter Senge in his book The Fifth Discipline covered in detail systems thinking, another unique discipline, using the CLD as its centerpiece.

So the question is: How does CLD apply to Six Sigma? Quite simply, it is the causal loop diagram’s unique ability to identify and visually display intricate processes and root causes. Every system behaves in a particular manner due to the influences on it. Some of these influences can be changed, some cannot, and some can minimized. Causal loop diagrams bring out the systematic feedback in processes by showing how variable X affects variable Y and, in turn, how variable Y affects variable Z through a chain of causes and effects. By looking at the all the interactions of the variables, the behavior of the entire system is discovered. With a CLD, a practitioner no longer needs to focus only on one interaction between two variables, but can focus on the entire system, along with its many variables and its many causes and effects. Only through this thorough analysis can a Six Sigma Black Belt or an organization make changes that are lasting in nature.

First, it is important to understand the structure used to create a causal loop diagram. CLDs consist of arrows connecting variables that show how one variable affects and impacts another variable (Figure 1).

Figure 1: Examples of Causal Loop Diagrams

The top example in Figure 1 shows that the number of workers who call in sick affects the number of employees available to work. Additionally, each arrow in a CLD is labeled with a minus or plus sign. The minus sign denotes that the first variable causes a change in the opposite direction in the second variable. In this case, as the number of workers calling in sick increases, the number of employees available to work decreases. The minus sign is placed at the head of the arrow as shown in the middle example in Figure 1.

A plus sign is used to signify that a change in one variable causes the second variable to change in the same direction as show in the bottom example in Figure 1. Thus, as the number of employees available to work decreases, organizational productivity also will decrease.

So, when the plant manager says to the resident Black Belt, “Our productivity is decreasing drastically due to all the call-ins we have received from workers who are calling in saying they are sick.” A rookie Black Belt might quickly look for ways to increase the health of the plant’s employees through wellness programs such as free membership to a health club. Maybe the Black Belt would even suggest setting up a health clinic in the plant staffed by a resident nurse. Both ideas could possibly raise the health of the employees but it could come at a steep price to implement. But a more experienced hand would opt for a DMAIC improvement project.

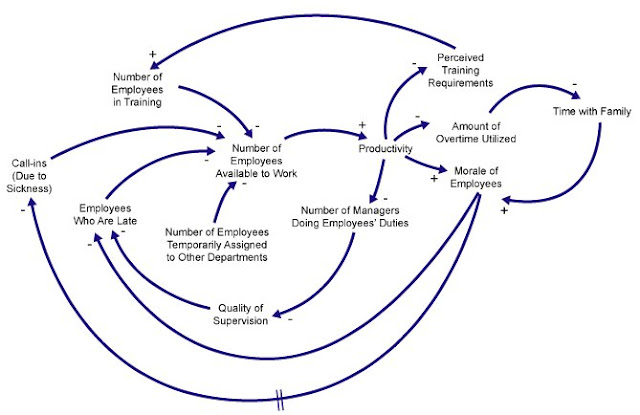

During the Define phase, the Black Belt identify the improvement goals sought by the business and determined they are consistent with the strategy of the company. During the Measure phase, data would be collected by asking the question, “What affects the number of employees available to work?” By talking to the human resources representative, along with various members of the management team, it can be determined that there are many other factors that cause the number of employees available to work to fluctuate. For example:

◉ Employees in training (in house and out of the area)

◉ Call-ins (due to sickness)

◉ Employees who are late

◉ Employees who are temporarily assigned to other departments

These variables, once added to the CLD, show a different picture:

Figure 2: Number of Employees Available to Work

Call-ins (due to sickness) may be drawing a lot of unwanted attention due to the fact some managers may have already had their manpower stretched thin due to the other reasons (training, lateness and temporary assignments).

The question that should be asked regarding the decrease in productivity is simple: “So what?” What are the effects of decreased productivity? Once again through observations, interviews, and document reviews, the answers become apparent:

Figure 3: Effects of Decreased Productivity

Interesting things are taking place due to the decrease in productivity. First of all, the “perceived” training requirements have increased. This might be due to the mistaken belief that it is the employees’ lack of knowledge that is causing productivity to decrease. Also, to make up for the loss of productivity (due to the limited number of employees) overtime is being used to keep employees at work longer. Morale also is impacted negatively. A majority of all workers want to do a good job. When productivity dips, tensions increase as managers frantically look for the solutions to turn things around. Often times, this pressure causes morale to dip. Finally, some managers are stepping in to do the work done by those absent employees.

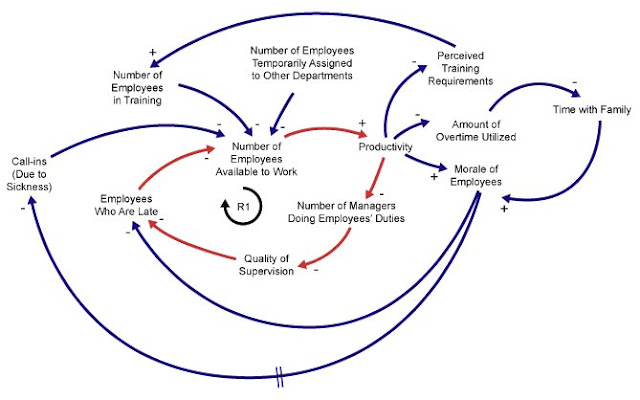

Though well intentioned, the effects of the interventions aimed at improving productivity can be as bad as the initial decrease of able-bodied employees (Figure 4).

Figure 4: The Effects of Interventions

As the perceived training requirements increase, it adds to the initial problem since more employees go to training and are unavailable to work. As the amount of overtime increases, employees spend less time with their families. This has a negative effect on their morale. As the number of managers steps in to do the duties of those employees who are absent, their ability to perform quality supervision decreases. This decreased supervision increases the number of employees who are late due to the fact their morale is decreasing and they also know that due to the lack of supervision, they will probably get away with it. A delay symbol (two vertical lines) are introduced in the above diagram which denotes that over an extended period of time, absences from work will increase as sickness takes hold due to decreased morale (due to continued use of overtime).

In causal loop diagrams, the arrows come together to form loops, and each loop is labeled with an R or B. R means reinforcing (i.e., the causal relationships within the loop create exponential growth or collapse). For instance, the more a person drives their car, the more gas they use and as they use more gas, they spend more money to buy the gas and so on, in a vicious, upward spiral. B means balancing (i.e., the causal influences in the loop keep things in equilibrium, or in balance. For example, as a person spends more money on gas, they begin to use more alternative methods of transportation (walk, take the bus, etc) and as they do this, they spend less money on gas.

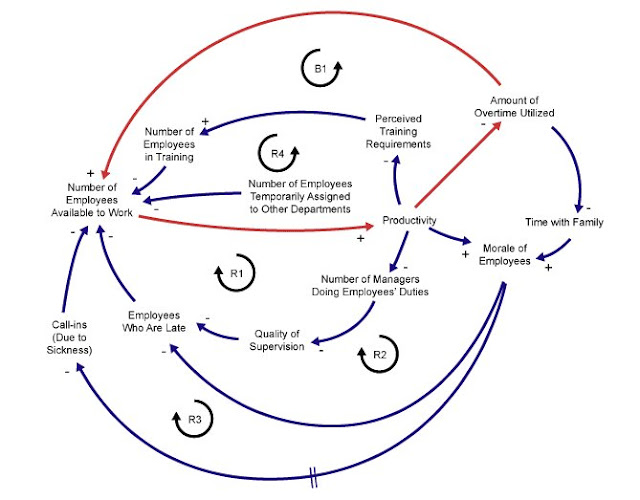

Figure 5: Labeling the Types of Loops

The first loop highlighted in red in Figure 5 is a reinforcing loop (R1). As more managers step into the gap by doing the job of the absent employees, their ability to effectively supervise decreases. Those employees who are not highly motivated (and not very dedicated) take advantage of this lack of supervision and begin showing up late for work. Their tardiness, however slight, causes the number of employees available to work to decrease which, in turn, negatively impacts productivity.

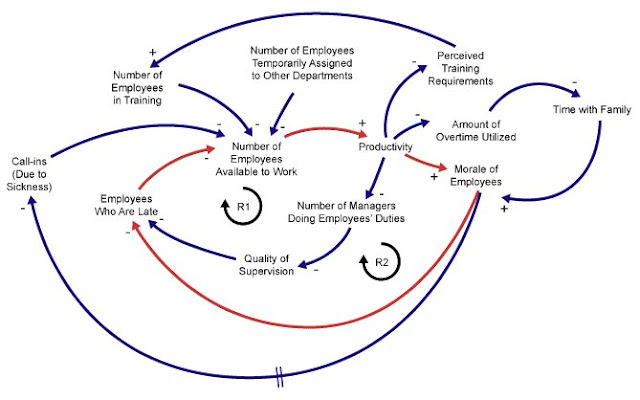

Figure 6: Another Reinforcing Loop

From the expanded CLD in Figure 6, another reinforcing loop (R2) appears. In this case, as productivity and morale both decrease, the number of employees who are late increases.

Figure 7: A Third Reinforcing Loop

In Figure 7, the next reinforcing loop (R3) shows the effect of long-term depressed morale as the number of call-ins (due to sickness) increases, thereby causing the number of employees available to work to decrease.

Figure 8: A Fourth Reinforcing Loop

In the CLD in Figure 8, another reinforcing loop (R4) shows how an increase in the perceived training requirements (due to decreased productivity) causes more employees to be in training and thus away from work, negatively impacting the number of employees available to work.

Figure 9: A Balancing Loop

The most interesting aspect of this CLD is that this company is using overtime as a method to put this process into balance. Balancing loop (B1) in Figure 9 shows that by increasing the amount of overtime, the company is able to have more employees available to work by basically having them work extra hours, thereby increasing their manpower without adding more people. Though this might work in the short run, it will have severe negative consequences in the near future.

So, by examining this CLD and by looking at the entire system, what could this company do to alleviate the problems? What are some immediate steps a manager or owner could do?

Here are a few ideas:

◉ Determine if those employees in training (especially those locally) can be pulled back early.

◉ Negotiate with those other departments that have personnel on assignment to them to see if their assignment length can be shortened.

◉ Evaluate the training being attended by employees (both currently and in the future) to determine if it has an impact on the strategy and goals of the company. If the training adds no true value or has little-to-no return on investment, consider canceling it to free up the employees.

◉ Reinforce human resources policies on tardiness and calling in sick. Remind employees that there are valid steps to follow when calling in sick or late and penalties for abusing these company policies.

◉ See if other departments can offer up employees on temporary assignment.

The above ideas are relatively low in cost, less expensive than a wellness program or an onsite medical clinic. This is the power of the causal loop diagram. It allows Black Belts and/or managers to step back and take a system’s view of the many processes. If properly created, the CLDs are powerful.

There are various software packages available that can help create a causal loop diagram. Also, there are many books and websites that provide additional information on causal loop diagrams. The causal loop diagram as another valuable tool that can help in the quest for valid and long-term solutions to problems.

0 comments:

Post a Comment