But what does that mean for an organization? For many, continuous improvement is a struggle. Companies solve problems by fighting fires, but that’s not continuous improvement. Instead, organizations must change how they think about getting better by improving how they improve.

But how? What happens if you want to do continuous improvement but don’t know where to start? What if your organization wastes too much time firefighting or operates in silos?

Is This Your Company?

Imagine an example: Your organization has struggled in the past to make real change happen. Departments generally work in silos and rarely come together unless it is to fight fires. You deal with problems every day and know what is preventing the company, at least in your area, from taking things to the next level. But you have never been asked for your perspective.

At your next monthly meeting, your leadership team pulls people together to focus on a key issue and promises that this time will be different. You can see the eyes rolling already. First, the project has no clear timeline. Second, what are you working on? The goal and measurables expected are unclear. Many people in the room have questions but few raise them. When are tasks due and who will do them? Who is leading this project? Is anyone being held accountable? Why are you working on this now?

People know they are on a team, so you schedule a follow-up meeting to come up with ideas for addressing the key issues. Right away, you can see how things are going to go. One or two people do all the talking and are already shooting down ideas as too difficult, lacking management support or being too costly. The rest of the group, if they are participating at all, are distracted with their laptops as they answer emails and fight fires back at their regular jobs. A few ideas are deemed worthy and you discuss what to do with them. But as time passes, the group meets less frequently due to scheduling conflicts and progress slows. Eventually, the work stops altogether.

When leadership asks for an update, the group confidently states that they have identified some real steps that can be taken to address the key issue but haven’t done any of that work. Frustration mounts as effort is perceived as wasted, and any implementation is delayed as leadership moves on to other priorities.

As efforts like this are repeated, culture begins to suffer. Employees don’t feel heard and leadership is frustrated at a lack of results on key issues. Ideas are raised like starting to do more “360 feedback” and employee surveys, but will they help? You don’t think so but are thankful that you can still contribute in your regular role.

So much for making real change happen.

How can you do continuous improvement better? Here are five steps any organization can embrace to get started on the right path.

Step 1: Plan Projects More Effectively

Like any effective initiative, better continuous improvement starts with better planning. What is so hard about planning a project? Organizations struggle to plan projects effectively for two main reasons:

1. They generally know what the problems are but don’t start in the right place for fast action.

2. They don’t spend enough time on the details before launching their teams.

First, most companies, especially if they ask employees close to the work, can do a decent job of figuring out what their problems are – at least the major problems. If the employees don’t know what the real problems are, robust root cause analysis may be required before project planning can begin. Once armed with the right problems, though, many organizations still struggle to get to work. You can take steps to improve in this area simply by starting with the big problems and breaking them down into smaller pieces until you find projects that can be accomplished with small teams.

Second, companies are usually so eager to improve that they launch teams with little time spent on the critical logistics needed to ensure success. Questions go without concrete answers. Who is leading the team? What functional expertise is needed to ensure you have a broad range of input? Do you have a clear project charter? And, most critically, when is this team expected to finish?

Figure 1: Set the Stage

When planned properly, projects are launched with the right team in place, the right person (or people) to lead them, a clear project charter from which to work and a project schedule finalized to hold people accountable.

In short, well-planned projects start sooner, get going faster and get better results from more engaged employees.

Step 2: Work in Teams to Brainstorm Solutions

Teams are a hot topic in business. From apps that promise to get teams working together more effectively to video conferencing and webinar technology, there seem to be solutions around every corner for making it easier to bring groups of employees together to solve problems. But do any of these solutions address what a team will accomplish when they get together? No!

When we say, “work in teams to brainstorm solutions,” what we mean is simple: You must recruit people from areas directly affected by the problem you are trying to solve. You must give them a roadmap and a process for brainstorming solutions. Finally, you must create an environment where the best ideas can win.

Critically, we believe teams should start with brainstorming ideas because that is where the energy is! In most cases, front-line employees are passionate about solving problems they work with every day – not about learning tools or methods or techniques.

This step is all about ensuring your teams are productive when they get together. Remove the politics, ownership and heartache that usually occur when people try to solve problems as a group. You do that by avoiding things like judging ideas too quickly, making top-down changes, not holding people accountable and ignoring the front lines.

When teams are working well together, solutions get more buy-in because those close to the work were involved and employees get excited about working on a team that gets results.

In short, teams excel when they are free to brainstorm what to do about a problem and empowered to go and solve it.

Step 3: Turn Ideas into Action – Fast

Far and away the most common complaint we hear about change initiatives is speed – or a lack thereof. Change simply takes too long. So, this step is all about doing what you can to turn ideas into action fast.

How? By flipping the script on choosing what to work on. Most companies choose first the biggest ideas that are likely to make the biggest impact on their mission. This is wrong. Too many organizations bite off more than they can chew and get stuck trying to implement world-changing ideas.

Think back to planning projects effectively in Step 1. If your project is planned appropriately, you will have a planned end date. This is where you can flip the script. Choose the ideas that give you the best combination of impact and speed based on those you can take significant action on before your team wraps up. With an eye toward what can actually get done, teams stay motivated to hold each other accountable with realistic and achievable benchmarks.

Figure 2: Choose Your Projects Wisely

Ideas get turned into action fast when organizations work on the right ideas and capitalize on what individuals do best – taking what needs to be done and actually doing it.

Step 4: Track Results and Sustain the Gains

Tracking and measurement are never going to be the sexiest part of any improvement campaign, but they are critical to success. Executive sponsors care about many facets of any campaign, but nothing speaks louder than concrete results. (In the words of Jerry Maguire, “Show me the money!”)

By tracking the action items of each individual idea, reporting progress throughout the project and compiling results against the current state of performance, teams can take major steps toward validating their efforts and inspiring future teams to do more.

Additionally, one of the biggest hurdles improvement initiatives face is backsliding. What happens when the team disbands, and everyone goes back to their day jobs? Too often, this means things revert to where they were before. Nothing kills success faster.

To avoid this, effective teams sustain their gains by identifying potential red flags and putting plans in place to overcome them. They predict who and what may stand in the way of their success and work, in advance, to get those people on their side.

Accurate tracking and compelling control plans help build the case for future projects by showing what is possible.

Step 5: Transform Your Culture

All of this is no good if the culture doesn’t change. Building fast-change capability into your organization is about installing the four previous steps and letting the results take over. People start to feel more motivated to contribute ideas and open to new solutions. Change becomes easy and fun, working in teams becomes exciting and fear of failure disappears. Employees also learn to think about the needs of their customers and how processes work to effectively, or ineffectively, provide value to their stakeholders.

In short, culture goes from a company where only a select few think about improvement to one where it becomes part of everyone’s job.

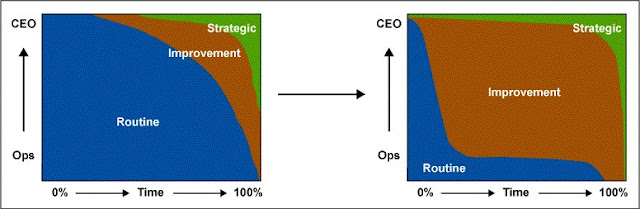

Figure 3: Increasing the Space for Improvement

These five steps are not new. Organizations often embrace these five steps by launching rapid action/improvement events, but any effort to improve should use these steps as a guide.

Is This Your Company? – Revisited

Imagine our previous example instead went something like this.

At your next monthly meeting, your leadership team announces they are sponsoring a project to solve a key business issue and have pulled together a cross-functional team of front-line employees like you to help. They lay out a clear calendar with a project end date and describe the goals in a charter with clear expectations and deliverables. They nominate one of the group members to be the team leader and give the team a roadmap to follow for brainstorming ideas and acting on them.

At the next meeting, the real work begins. The team follows the brainstorming roadmap to come up with dozens of ideas for solving the problem and everyone is engaged. By sorting and prioritizing, the best ideas are selected and assigned to individuals for fast action. The initial meeting concludes with people feeling excited because real work has already been done and people know what they must do to make progress and by when. People will be held accountable.

Because future meetings were scheduled at the beginning of the project, attendance is not an issue and leadership stays up to date. Progress is steadily made as the project nears completion. Ideas get implemented because people are bought in and results are tracked to show the impact. The team disbands feeling good about what they have accomplished in a short amount of time.

As you go about your regular duties once more, you notice a change in the way people are talking about problems. Instead of complaining, ideas for solutions start to flow. People see what you and your colleagues were able to accomplish and start to embrace faster change. This doesn’t have to be so hard after all. All because the mindset toward improvement changed and a plan to improve was put in place.

What’s Holding Your Organization Back?

Why hasn’t your organization already implemented these five steps to success? It’s probably one or more of the following issues.

◉ Too many silos: In most organizations, it is difficult to foster collaboration between stakeholder groups, so implementing new ideas is a struggle.

◉ Lack of confidence in a process: Most organizations have tried various ways to tackle the continuous improvement challenge, but traditional tools are too complex. Using no process, however, is even worse!

◉ Lack of results: In the end, projects take too long and solutions – even when eventually implemented – seldom stick.

◉ Lack of time: People are busy. Those close to the changes that need to improve do not have time to improve the business while they fight fires.

The key is to use simple tools that make embracing continuous improvement easier than ever.

0 comments:

Post a Comment