What is meant by people complexity? High people complexity problems are typified by change environments that involve multiple stakeholders with conflicting and/or competing needs. In manufacturing, extreme people complexity scenarios rarely come into play once the technical solution has been proven rationally. But, in transactional environments, this is not so simple.

Mixed Problems in Transactional Six Sigma

Transactional Six Sigma issues are often mixed problems with mid- to high-technical complexity, and almost always have high people complexity. Processes in transactional environments tend to have three important characteristics.

1. Transactional processes cut across multiple functions, and consequently:

◉ Sometimes competing and conflicting priorities of these functions come into play.

◉ Existing power politics that may exist between the leaders of these functions become entangled with the improvement effort.

◉ Ownership of the entire end-to-end value stream may not exist formally within the organization structure.

◉ Nobody has the final say on whether something goes or not.

2. Transactional processes are often “invisible” because there is no shop floor line, and consequently:

◉ Perceptions of what constitutes the process may be unclear.

◉ People only see their part of the process and sometimes may not even be aware of the other parts.

◉ The lack of a process view of work means readily available data is not present.

◉ Collecting data can become an exercise in influence (if handled correctly) and power politics (if handled badly).

3. Transactional processes have intangible products (in the form of services or completed transactions), and consequently:

◉ People and people-related factors influencing perceived product quality are typically significant, and improving these people factors are normally not just a function of tweaking of settings but cultural change.

◉ Most of the people working within value streams rarely see a completed product because the product is largely a function of the customer’s entire interaction with the organization (and only the customer sees the whole).

Because of the lack of a process view of work, improvement actions are almost always targeted at local optimization (improvement projects are functionally scoped). Global optimization across the entire value stream is unheard of in some transactional organizations and those that attempt it have typically found it very difficult to do.

This is largely because people complexity is much lower when the project is scoped within functions. However, the sum of local optimization does not lead to global optimization. Paradoxically, for global optimization to occur, it is sometimes necessary for some parts of the system to be sub-optimized.

Managing the People Side of Improvement

The Lean Six Sigma DMAIC toolkit is excellent for solving technical complexity problems. However, the current Six Sigma core training curriculum barely mentions the people side of improvement and is sorely lacking in tools designed to optimize people-centered problems.

The classic approach to managing the people side of change follows a patient/doctor model, also known as the “sickness model.” Often an expert consultant is brought into an organization that is experiencing people complexity issues to diagnose the root causes. Then medication in the form of a change intervention is proposed and, if approved, implemented under the expert guidance of the consultant. This model has largely failed. Indeed, an early champion of this approach, Marvin Weisbord (who wrote the definitive text on it, called Organizational Diagnosis) has since rejected it and is now the leading champion of what he calls third wave consulting.

Figure 1: Progress of Solving People Complexity Issues

Third wave change management is based on four practical guidelines:

1. Assess (and harness) the potential for action: This means moving away from diagnosis toward assessing and exploiting existing readiness for change. (Factors are committed leadership, good improvement opportunities and energized people with passion).

2. Get the whole system into the room: This means getting all of the stakeholders (including, in some cases, customers and suppliers) into the same meeting to work on joint tasks to optimize the larger system.

3. Focus on the future: This does not mean denial of current reality. Rather, it means that by focusing more of the group’s energy on what could be (vision) tends to yield more positive outcomes than being stuck in current reality.

4. Structure tasks that people can do for themselves: The underlying principle here is that in high people complexity environments, people are more likely to implement improvements that they have a hand in developing. Involvement breeds commitment and passion, which in turn breeds success.

Need for an Integrated Roadmap

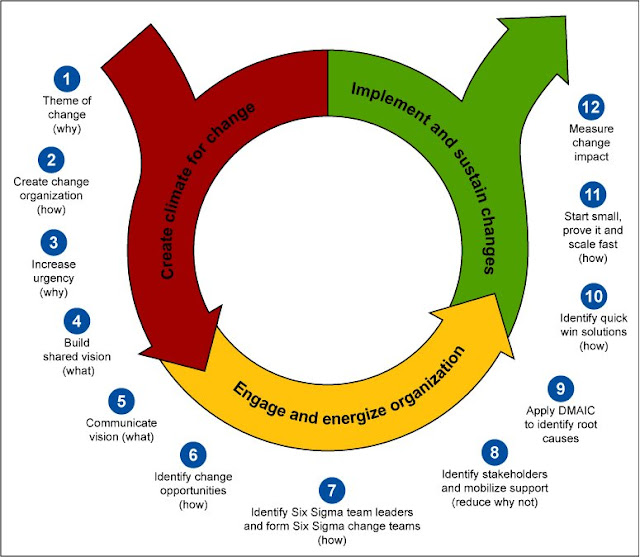

What is needed in a high technical and people complexity change environment is an integrated DMAIC/change management roadmap (Figure 2). The model suggested here is designed based on the third wave principles. Significantly, DMAIC is just one of the 12 steps in the model and occurs late in the plan, once the organization is ready for globally optimized change.

Figure 2: 12 Steps of Integrated DMAIC/Change Management Model

The table below shows a snapshot of the kinds of tools that are employed in the three phases of change.

0 comments:

Post a Comment