Colleagues at a Lean conference I attended supported this claim, claiming greater than 90 percent failure rates in their experiences. I do not have the data to support this anecdotal “data,” but these numbers beg the question: Why? If true, this failure rate for Lean initiatives would seem discouraging. Or is it?

Failure Is Good

Have you heard the phrase, “fail often, fail early, fail forward”? Failure is not a subject that you should fear; failure should be embraced. You should seek out failure to learn and improve. However, for many organizations, when their first “failure” happens or when Lean initiatives call for harder work than anticipated, they quit and blame the failure on Lean. Organizations may be quick to move on to the next flavor of the month after just a quick exploration of Lean. This creates a frustrated and discouraged workforce. Sustainment only happens when organizations are truly committed to true and lasting change – a relentless pursuit of cultural transformation.

What can you learn from the idea that more than 90 percent of Lean implementations fail?

Leadership Is Everything

I have worked with many organizations from nonprofit to government to manufacturing and ranging from small businesses to billion-dollar corporations. Leadership has been the key component to sustainment or collapse of their Lean initiatives. It is imperative that an organization develop its leaders to embrace the idea of being a learning organization supported by an enabling operating system. Every leader in the organization must be committed. Cultural transformation is hard. Humans can be difficult. There are many obstacles you will face in your Lean journey, but when you are committed to success, you don’t let anything stand in your way!

A Gallup Study found that 50 percent of people who leave their jobs do so to get away from bad leaders. Seventy percent of employees are not engaged at work. Gallup also found that 51 percent of managers not only are not engaged but 14 percent are actively disengaged!1

For Lean initiatives to be sustained, you need a different leadership system, a different management system, than what was in place before Lean. If you don’t deploy a different leadership system, your initiatives will fall apart. If you manage the same way – with the same meetings and same metrics – you will get the same behaviors and results instead of the improved results you are seeking. Unless you change the way you manage, Lean initiatives will not be sustained.

Be a Servant Leader

As a Marine, I attended survival, evasion, resistance and escape (SERE) survival training – it’s an advanced code of conduct course. All military personnel get their initial code-of-conduct instruction during basic training, where they are taught an American service member’s legal responsibility if captured by enemy forces. SERE goes beyond that; it starts with survival. It was in SERE training that a young captain showed me what it means to be a servant leader.

After many days of limited rations, the enemy forced all the officers to eat first. As the rest of us stood in line waiting for our small bowl of soup, the enemy officers kicked over the serving table and all the remaining soup spilled onto the ground. The young captain and a few other officers were the only individuals who had already received their bowl of soup. Without hesitation, the captain ordered the other officers to disperse their soup among the rest of the group. He was first to share. I would have followed that man to the ends of the earth. What an amazing example he gave me of a true servant leader.

A great Lean leader is also a servant leader (see table below). They choose others before themselves. They are humble, listen and build trust. They see conflict and are quick to resolve it. A Lean leader never abuses their authority. They encourage collaboration, trust and empowerment.

| Servant Leadership Checklist | ||

| Is self-aware | Has foresight | Collaborates |

| Is humble | Has foresight | Is trusting |

| Has integrity | Doesn’t abuse authority | Coaches |

| Is result-oriented | Has intellectual authority | Resolves conflict |

You may already have some or many of these qualities. But how do you become a great Lean leader?

Lean Leadership Development

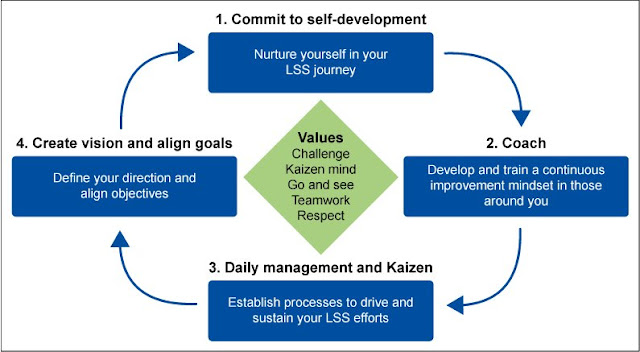

Dr. Jeff Liker’s Lean Leadership Development Model (as described in The Toyota Way to Lean Leadership) will help you break through development plateaus and create a sustainable future for Lean thinking in your enterprise. (See figure below.) When leaders adopt this model as their “system,” their way of managing, amazing things begin to happen.

Lean Leadership Development

1. Commit to self-development. There are a few steps to managing your personal self-development following the plan-do-check-act (PDCA) model.

1.1 Create a vision for where you want to be in the future. This will become your true north. Every decision should then be aligned with this true north. Most of us find it easier to motivate ourselves to learn and improve if you have a purpose in doing so. Your personal vision will give you a clear idea of where you want to be in a few months or years – and why you want to be there. It’s a crucial part of developing this purpose.

1.2 Plan your personal development journey. Once you are clear about where you want to be, you can start planning how to get there. Who do you need to meet? What books or podcasts should you listen to? What mentors do you need to reach out to and on what topics? Drawing up a personal development plan is not essential, but it does make the planning process more realistic. I usually create a one-year plan with 90-day PDCA cycles.

1.3 Carry out your plan. Don’t wait to get started. You can adjust as needed. It is often a good idea to keep a record of your personal development. This is done in the check phase. By writing down key developments in your learning and development as and when they occur, you will be able to reflect on your successes later. Regular review of your personal development plans and activities will ensure that you learn from what you have done.

1.4 Act on your result. It will also ensure that your activities continue to move you toward your goals, and that your goals or vision remain relevant to you.

2. Coach and develop others. The Center for Creative Leadership gave us five areas to assess ourselves as effective leaders developing others.

2.1 Relationships. How well do you establish boundaries and build trust? This cannot be done from your desk. You need to go to the gemba – go to where your team members are and spend time with them. Ask them to show you how they do their job. Show genuine interest in their work and in their personal lives.

2.2 Assessment. Do you skillfully help others to gain self-awareness and insight? Your team should see you and hear from you daily. You should set up a regular cadence of positive and constructive feedback for your team members. A good leader doesn’t just tell. Engage your team members with strategic questions that can help them discover opportunities for improvement themselves and then be sure to give them credit.

2.3 Challenge. Do you effectively challenge the thinking and assumptions of others? You must be careful with this one because you don’t want your team to think you are micromanaging them. Their learning will come through their own mistakes. Allow them to experiment, but challenge strategically with good questions.

2.4 Support. Do you listen well? Do you understand things from your team members perspective?

2.5 Results. Do you help your team members set meaningful goals, hold them accountable and help remove any roadblocks they may have for successes?

3. Support standard work. Leader standard work is a tool that defines what a leader must do to ensure a successful day. It ensures process integrity. The best way to build and sustain a continuous improvement culture is incremental. Daily accountability is key! By following your own daily standard work, you will begin to solve problems quickly, creatively and permanently. Collaboration will become a regular occurrence as your coaching and developing of others becomes a regular habit. Personal productivity and time management are important to assure complete success at the end of each day. Your leader standard work can help with this.

4. Create vision and align goals. There is a certain level of stability within your team and your processes that is necessary to create vision and align goals throughout your organization. Once that stability is reached, it is time to move ahead with your vision and get alignment with goals. People perform best when they have a purpose. When they understand not just what to do, but why it’s important. It is best to know your team well enough to create a shared vision.

The Traits of a Lean Leader

Change leader John Hamalian wrote about six traits of a Lean leader.2 In an organization committed to cultural transformation, leaders need to be intentional to develop these traits within themselves.

1 and 2. Embrace the journey and relentlessly pursue perfection. As previously stated, Lean needs to be accepted and embraced by the organization and every single leader. Lean needs to be the way you do work. It’s not a tool or a step toward something else. Continuous improvement is a never-ending journey toward perfection. You’ve heard of organizations that started their Lean journey just to quit when the going got tough. Your journey toward perfection will not be easy. Thomas Edison once said, “Opportunity is missed by most people because it is dressed in overalls and looks like hard work.”

Lean expert and FastCap CEO Paul Akers is a relentless, maniacal cheerleader for Lean. He arrives at the office and talks to everyone, asking them to show their improvements. He creates videos of every Kaizen and shows them to the whole company at the daily huddle. Paul celebrates every improvement, no matter how small, every day. He may be more excited about the improvement than the person who’s made it! How many presidents/CEOs are willing to make that commitment? Not many. It takes hard work and a total embrace of the journey.

3. Be a fanatic about customer focus. Having a relentless focus on the customer is the path to sustained growth and profitability for any organization. This fanatical customer focus must become everyone’s responsibility, not just the leaders. The customer is the only reason you have a job. If customers are not your focus, then you might as well go home because you are not needed. Every employee must understand what they need to do to maintain and add value to both internal and external/end customers.

4. Champion simplicity. The biggest reason so many leaders fail to maintain a robust, workable Lean system is their desire for complexity. This desire seems to be human nature. You begin simply enough, but then you add more levels of complexity until eventually you have a system that takes far too long to maintain. To avoid that cumbersomeness, you must keep things as simple as possible.

When I was serving in the Marine Corps, I was taught a valuable lesson about communicating strategy to all levels of an organization. The lesson has come to be known as “Napoleon’s Corporal.” Napoleon recognized how vital it was to have an enlisted soldier in the planning process. While creating their battle plans and war strategies, Napoleon made sure there was a corporal in the room. Once finished, he would ask the corporal if he completely understood the plan. If he said, “Yes, sir!” Napoleon would carry out the plan knowing it could be cascaded down to the ground troops, who would understand it well enough to execute it. If the corporal was unclear, then the group would continue working on the plan until the corporal understood it.

Another concept used in the military is KISS, or keep it simple, stupid. When communicating expectations to our teams, they need to be communicated in a manner that everyone can understand.

5 and 6. Live the Gemba and be authentic, upstanding and respectful. The auto manufacturer Nummi, a partnership between Toyota and GM, yielded extraordinary results based on these leadership traits. The two companies selected GM’s plant in Fremont, California, for Nummi’s location, which was considered to have “the worst workforce in the automobile industry” by United Auto Workers. Sex, drugs, alcohol and gambling were all rampant on the job. Despite this, Toyota developed a culture of engaged problem solvers.

The Fremont workers went to Japan for a full immersion in Toyota’s Production System (TPS). The traditional way of managing employees in the United States was top-down and usually done from the office. This was quite different than in Japan, where the leaders embraced a gemba style of leadership and respected the expertise of those closest to the value-add work. In a traditional management system, employees are told about decisions after they are made and are expected to just do what they are told. This coercive type of system does not provide respect to employees.

At Nummi, after the full immersion in TPS, the employees were empowered to make decisions, although sometimes within boundaries. Standard work provided a baseline and starting point for consistency. Employees measured their results based on a known expectation and they were cross trained to move wherever the greatest need was. Leaders were placed at the gemba, where the value-add work was being done, so they could ask questions and help to remove roadblocks, problem solve, mentor and coach.

0 comments:

Post a Comment