In the aerospace industry, zero defects has been the driver for customers and competition since Phil Crosby and his team at the Martin Company provided the Army with a zero defect missile in the 1960s. This is not a new concept but the first question that comes to mind is: how much do we need to invest before we achieve zero defects? Once we embrace the fact that zero defects is not a final destination but a journey, it becomes easier to start asking the right question: how do we get started?

This article will attempt to provide a low-cost way of deploying zero defects with little or no investment. First, a review of a generic zero-defect deployment roadmap for years one, two and beyond that is based on my experiences from three different industries – chemical, medical and aerospace. Then we will look at the most recent deployment of zero defects from my present place of employment. Finally, I will reflect on some guiding principles that are keys to the speed and sustainment of the zero-defect culture.

The goal is to arrive at a state where it is part of the culture to continuously address and prevent small problems from becoming projects – or worse, defects. The roadmaps below present a generic roadmap for years one, two and beyond (Figures 1, 2 and 3). The last section shows what a stable state looks like at a high level. The example of Elbit’s journey follows the generic roadmaps.

This article will attempt to provide a low-cost way of deploying zero defects with little or no investment. First, a review of a generic zero-defect deployment roadmap for years one, two and beyond that is based on my experiences from three different industries – chemical, medical and aerospace. Then we will look at the most recent deployment of zero defects from my present place of employment. Finally, I will reflect on some guiding principles that are keys to the speed and sustainment of the zero-defect culture.

Generic Deployment Roadmap and the Elbit Systems Journey

The goal is to arrive at a state where it is part of the culture to continuously address and prevent small problems from becoming projects – or worse, defects. The roadmaps below present a generic roadmap for years one, two and beyond (Figures 1, 2 and 3). The last section shows what a stable state looks like at a high level. The example of Elbit’s journey follows the generic roadmaps.

Figure 1: Year 1 of starting a zero defect or any continuous improvement program. The new addition indicates a key success factor that is commonly missed during preparation.

Year 1 needs to focus on two things:

1. A pilot that will exhibit the potential of using the tools

2. Setup for a long continuous improvement journey

Selecting the pilot is typically not difficult if you are working with management. The latter requires a great deal of information gathering, training at a high level and putting mechanisms in place that will serve as drivers for continuous improvement.

Figure 2: Year 2 of starting a zero defect or any continuous improvement program. This is the year of standards, maximizing communication and coordination between functions and teams.

Year 2 needs to focus on building speed of continuous improvement – training and structure. The trainers need to expect to be teaching, coaching and following up continuously.

Figure 3: Year 3 and beyond of any continuous improvement program. This is the year where we start sharing best practices, sustaining the speed of improvement by building it into procedures, how we plan budgets and continuously train the organization.

Year 3 is the first year where the continuous improvement journey should follow a standard recurring set of activities.

Example from the Journey at Elbit Systems (Supplier of Vision Systems to Aerospace)

The zero defects journey at Elbit Systems follows the policy of “don’t ship a defect” to the customer, “don’t make a defect” during assembly and “don’t buy a defect” from the supplier (Figure 4).

Figure 4: Journey of Elbit Systems from plug and pray (i.e., low yields at test) to plug and play (100 percent first-pass yields). We sustained a zero-defect state at final test in March 2017. We reduced 30 percent of defects at assembly by June 2018. The challenge now is “don’t buy a defect,” which entails getting our suppliers to embrace a zero-defect journey.

Zero defects during year one was all about getting the final test yield to 100 percent. The second year was about putting process controls (Figure 5) in place, educating the suppliers and performing failure mode and effects analysis (FMEA). After that, during weekly zero defect reviews with management, we used FMEA to show the top risks and activities to reduce the defects.

Figure 5: Process control deployment is critical to standardizing and sustaining gains in zero defects.

The important thing to note with the use of the FMEA is that we not only addressed ongoing defects but also ensured that potential risks are not realized during production.

Guiding Elements

Here are some elements that are critical to both speed and quality of deployment:

1. How can we achieve zero defects faster than anyone else? By learning faster than anyone else. I recommend using just-in-time training and a structured approach. It may be better to train only when there is assurance of immediate implementation such as just before a Kaizen or a scheduled activity. Structure of DMAIC (Define, Measure, Analyze, Improve, Control) or PDCA (plan, do, check, act) can be easily driven by requiring A3s. Note: Be aggressive about use of visuals and data in A3s; remind everyone that A3s are stories not mere record-keeping.

2. How can we drive zero defects through the organization and external parties? The application of tools. Asking, “which tools did you use,” should start and end every discussion.

3. Remember Lean is about creating wealth by eliminating waste and creating value in its place. Six Sigma is about making a change based on data (not based on opinions or tweaking). Data is the lifeblood of any continuous improvement program.

4. Figure 5 shows how different tools work together to control process performance. Note: Just by making team members aware of how the process is behaving with numbers can change their behaviors and drive them to make the right decisions. Eighty percent of the benefits from implementing process controls comes from simply charting failures immediately after they happen.

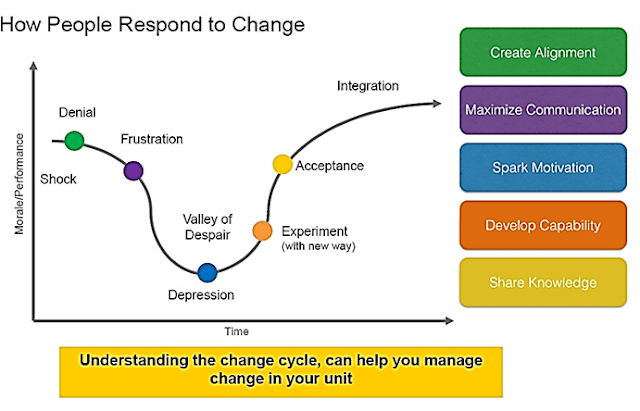

5. Figure 6 is the most useful representation of the change curve and extremely useful when preparing for a Kaizen event or managing a process improvement project.

Figure 6: The Kubler Ross Change Curve and how to handle every change situation.

0 comments:

Post a Comment