Six Sigma is set of techniques or set of management techniques carried out to improve business processes by reducing the probability that an error and defect will occur.

Six Sigma is a disciplined, using statistical based data driven approach and also a continuous improvement methodology for eliminating defects in a product, process or service.

Six Sigma methodology firstly developed by Motorola and company then it became popular when General Electric achieve the excellence in business by applying Six Sigma Methodology in the early 1990s. Now there are thousands of company in the world who are adopted Six Sigma as a way of doing of business.

Success of Six Sigma implementation is based upon five main principles:

◈ Concentrating on customer requirements

◈ Using accurate measurements to do error-less statistical analysis to understand improvement opportunities for building a solution for identification of root cause of problems (variations)

◈ Being efficient and capable to eliminate variation to continually improve the process.

◈ Involving manpower in Six Sigma cross-functional teams.

◈ Being thorough and being flexible

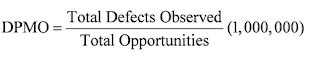

1. DPMO (Defects Per Million Opportunities)

Six Sigma methodology firstly developed by Motorola and company then it became popular when General Electric achieve the excellence in business by applying Six Sigma Methodology in the early 1990s. Now there are thousands of company in the world who are adopted Six Sigma as a way of doing of business.

Principles of Six Sigma:

Success of Six Sigma implementation is based upon five main principles:

◈ Concentrating on customer requirements

◈ Using accurate measurements to do error-less statistical analysis to understand improvement opportunities for building a solution for identification of root cause of problems (variations)

◈ Being efficient and capable to eliminate variation to continually improve the process.

◈ Involving manpower in Six Sigma cross-functional teams.

◈ Being thorough and being flexible

What are the main concepts in Six Sigma?

1. DPMO (Defects Per Million Opportunities)

2. Critical to Quality:

Critical to quality is one of the major concept in Six Sigma methodologies because the quality can affect the whole business objective or Goal.

Critical to quality means the measurable characteristics of a product or service which must be matches the customer requirement of product or service.

3. Defect:

The defect is defined as a product or service characteristics which are not the customer want.

4. Process Capability:

Process capability can be defined as a ability of your business process to deliver or produce a service or product which are meeting the customer demands.

5. Variation:

Variation term is a bit different in Six Sigma methodology, here variation means after delivering service and product the control person can measure the difference between the what customer sees and what they actual feels after acceptance of product or service.

6. Stable Operations:

Stable operations means not only the stabilizing the process but businesses have to ensure that the process of business in consistent to reduce the gap between what customer sees and feels.

Customer & Product driven Features of Six Sigma Methodology:

1. Six Sigma is aim to avoid waste and in effeminacy, so increasing customer satisfaction by delivering what the customer is really expecting.

2. Six Sigma is strictly structured and disciplined structure methodology, which has very specific for the particular participants.

3. Six Sigma is statistical data driven methodology which requires accurate or error-less data to perfectly analyze the process.

4. Six Sigma is not just about the improving quality and increase the sale its about changing results in the financial statements also.

5. By applying Six Sigma in your business you are successfully achieve the below milestones what we called the business success facts:

◈ Improving Process

◈ Lowering Defects

◈ Increased Profit

◈ Increased Customer Satisfaction

◈ Reducing Costs

◈ Reducing Process Variability

Six Sigma Methodologies totally revolves around one main cycle called DMAIC

DMAIC

DMAIC is a data driven quality strategy used to identify opportunities in the process to make improvements and reduce the errors and defects

D - Define-(Defining the problem, opportunities, business objectives, customer demands)

Here you define what opportunity are you looking for or we can say what problem you are trying to fix or simply what new business objective or customer demand you are trying to complete.

M - Measure performance

This is the crucial step for professional who are seeking out any opportunity to improve the service, process or product. Measurement is critical in the step and it must be accurate because you are trying to build solution on the basis of that measurement. In this process the measurement team has to focus on the process and what customer actually cares about.

A - Analyze opportunities

In this step the team has to analyze what is causing the problem and where there will be the opportunity to improve the process or service quality or cost or product. In this step team spend their time on finding root causes of problem and building the solution depending upon the results.

In this step mostly experienced and Six Sigma Green belt certified person analyze. The teams have to develop hypothesis according to finding and results and then define then work to prove or disprove the hypothesis.

I – Improve Performance

After implementing solution into process the teams have to concentrating on the factors which are crucial for improving the process or service or product. In this step the team have to collects data to check if there is measurable improvement or not if yes then the team will follow these process as a core process than pilot process and then finally improve the baseline ultimately it leads to improve the service quality or product quality which finally meets the customer satisfaction.

C - Control performance

This is the step in which team have to control the process and sustain the changes and improvement they made in the process or service. This is one of the most important activity required by the business because sustaining the improved process is very important to hold the service quality or product quality ultimately to hold the customer.

Benefits of Six Sigma to Businesses:

1. Lowering Defects:

Six Sigma completely revolves around only one principle reducing defects and ultimately increase the quality of product or service. So when a organization have Six Sigma implemented in their process then the business will totally focus on that one principle based statistical data driven approach.

2. Reducing Cost:

This is one of the final and long term benefits businesses get when they have implemented Six Sigma in their process because Six Sigma implementing ultimately leads to reducing the defects which means saving of time, resources, power, manpower efforts and ultimately money.

3. Increased Customer Satisfaction:

Six Sigma and DMAIC implementation starts with measuring the variation means measuring the gap between what the customer actually sees and feels. So the successfully implementation completed and if it is sustainable for business then it will ultimately reduces the variation their services or product that means increased customer satisfaction and increased customer loyalty.

Benefits of Six Sigma Certification

1. Help to protect your organization to Avoid Errors:

If you are working in organization which needs improvement then your certification and skills gained during certification will help your organization to make better product or serve better service with minimum errors.

With Six Sigma certification and skills you will be able to improvise the process and increase the profit of your organization it will ultimately lead you to become a important asset for the company.

2. Higher Salary :

As per the survey on Payscale.com you can see that Six Sigma certified persons are getting highest salary and working in the top multinational companies.

3. Increase your managerial and leadership ability:

When you are working as a Six Sigma professional in an organization then you have to undertake all the factors like finance, manpower, resources before taking any decision or before implementing any changes in any process or service or product.

Those who are achieved with Six Sigma Black Belt Certification are work as a Change Agent in their organization they have better understanding and knowledge about process and how to make it make it better.

To work as a leader in Six Sigma field you must have knowledge and understanding of financial management and risk assessment to perform a job without a error.

4. Large scope for Six Sigma across all the Industries:

Many individuals thinks that Six Sigma is only beneficial to manufacturing industry but actually six sigma is applicable to all types of industry. Service industry like IT, healthcare, hospitality needs to improve their service to provide 100% satisfaction to customers with completing their business objectives so all the service sector needs six sigma professionals to improve their overall business process and to complete business objectives.

5. Increase your productivity and capability:

After completing six sigma certification you are completing responsibility by doing less effort so the ultimate result will be increased productivity and capacity to handle large projects easily with sustainability.

0 comments:

Post a Comment